It's 1:40 AM on a humid Tuesday, and the chamber sealer stalls again—seal bars hot, pump whining, operators tired. Our OEE on the packaging cell drifts into the 55–65% range by mid-shift, while scrap creeps up. Export audits for two Asian retailers are due in nine days. I’m the QA manager, and my phone is buzzing. The first question I get isn’t about technology; it’s, “Will today’s lots pass?” I need more than hope. I need control.

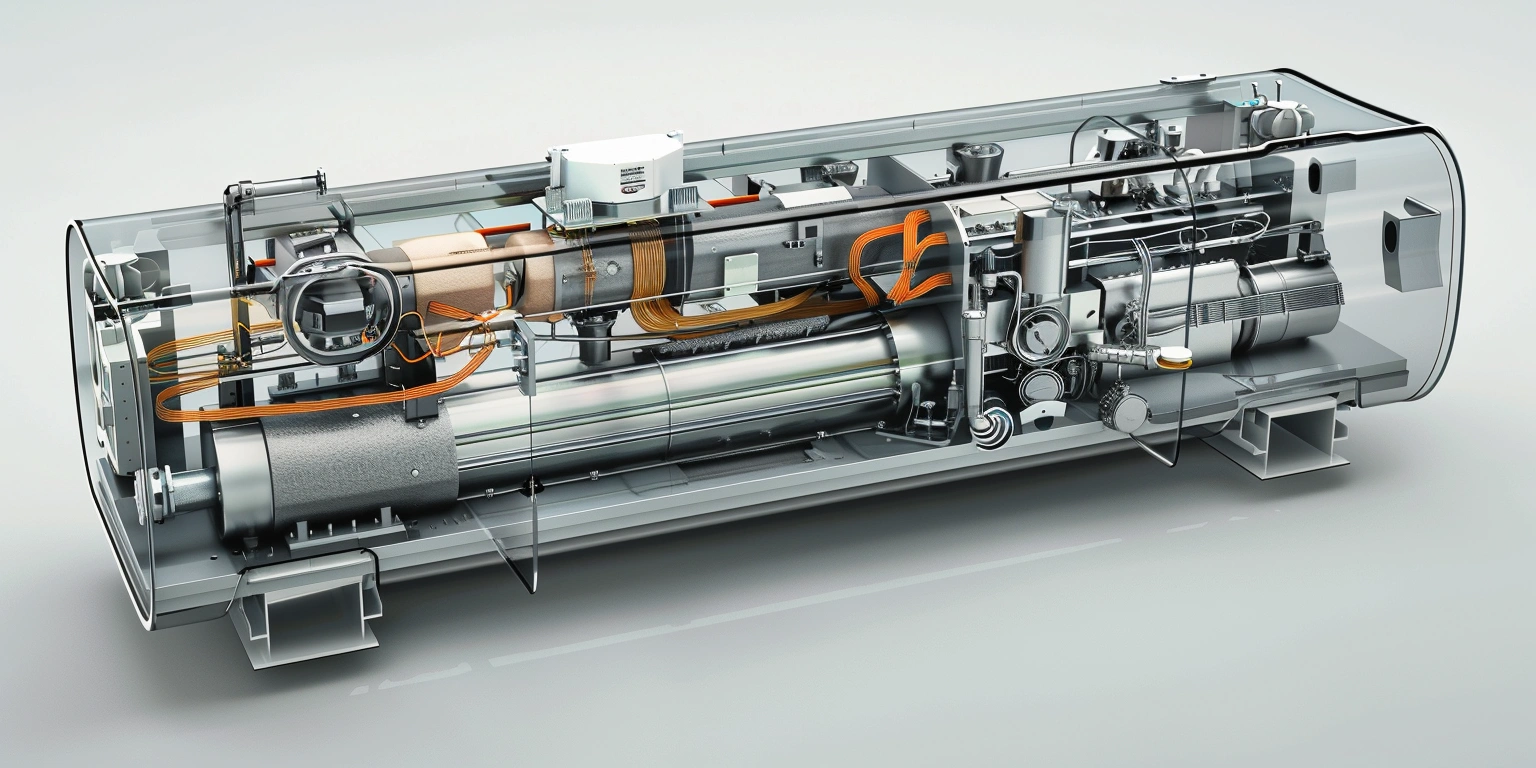

We had just invested in a vacuum-sealer upgrade that looked solid on paper: deeper vacuum, faster cycle, smarter HMI. In reality, our failure modes didn’t care about brochures. Seal integrity wavered when product moisture changed, residual oxygen edged above targets, and the cooling cycle felt off by a few seconds. We traced defects to three sources: film variability, vacuum stability, and heat profile drift.

Based on field notes from **ASFL** deployments I’ve reviewed (and lived), vacuum sealing’s limits don’t show up under lab lights; they show up under condensation, operator fatigue, and tight audit windows. Here’s how the problem actually behaves—and what made it manageable.

Where the Real Bottleneck Hides

In QA terms, the bottleneck isn’t just machine speed; it’s consistency under changing loads. Our line swings between dry snacks in the morning and high-moisture seafood after lunch. A fish vacuum sealer can look fine in a demo, then leak under actual brine and purge. The hidden issue: moisture vapor adds to the pump’s workload, so the vacuum curve flattens. Instead of a clean pull to −95 to −98 kPa, we see stutter and early plateau, especially when filter housings are damp. Residual oxygen in packs nudges from the 1–2% we plan for toward 3–4% during peak humidity. Not catastrophic, but enough to trigger extra sampling and stress.

The second place the bottleneck hides is film reality. We spec PA/PE films with tight gauge control, but supplier lots vary. We saw seal failures cluster when gauge drifted a fraction high—seal bars had to push more energy, and our time-temperature window shifted. Our FPY on seafood lots would hover around 72–78% under those conditions, while dry runs stayed closer to 85–90%. The machine isn’t lying; the inputs changed. The question is whether your controls notice early enough to prevent a pile of rework tickets.

The last bottleneck sits between people and screens. Operators often chase alarms by bumping seal time +0.1 to +0.2 seconds and think it’s solved. Sometimes it is, for 20–30 minutes—then defects drift back because the vacuum target wasn’t truly met. Our routine vacuum-decay checks caught inconsistent profiles after product changeover. The lesson: if your HMI logs only cycle count and alarms, you’ll miss the vacuum slope story that actually explains defects.

What Worked (and What Didn't)?

We tested three fixes. First, we tried a pre-dry cycle—pull a shallow vacuum, pause 2–3 seconds to vent moisture, then run the full pull. On seafood, this stabilized residual oxygen back toward 1–3%, and our seal appearance smoothed out. Second, we added a double-seal recipe for wet packs; it helped presentation and reduced edge-wicking in burst tests. Third, we swapped pump filters more aggressively—every 2–3 shifts during high-moisture weeks, not just on a weekly schedule. That cut the number of mid-shift vacuum alarms from 3–5 down to about 1–2. What didn’t help? Pushing cycle speed. It saved seconds, then cost us rework when the seal cooling window got too tight.

People ask me, “what is the best vacuum sealer to buy?” From a QA seat, the honest answer is that the best food vacuum sealer for your plant is the one that stays predictable when inputs wander. Chamber units handle moisture better than nozzle-style machines, but they need disciplined filter care and vacuum verification. Nozzle systems can be flexible, yet they struggle under brine without strong pre-dry logic. Consumer attachments like a foodsaver mason jar ASFL vacuum sealerealer have their place in R&D kitchens, but they aren’t a quality gate in production. Pick the approach that keeps residual oxygen in your spec window when the real world gets messy.

On materials, we validated two film families. A tougher seal layer handled seafood purges but demanded a longer cool. A more forgiving layer worked fine at speed on dry goods but showed dye wicking when we pushed seal temperature for fish. Neither was perfect, and that’s the point. There’s a trade between seal strength and cycle time. Our sustainable path was recipe discipline: distinct vacuum targets, seal times, and cooling profiles by product. Sounds basic. It is. But it moved our defect rate from the 4–6% band toward 2–3% on wet packs without chasing speed that would unravel quality.

Week One: What Actually Happened

We started with a pilot on Line 3: seafood in the afternoons, snacks in the mornings. Day 1 felt calm—new HMI screens, operators briefed, QA watching. By Day 2, the vacuum alarms returned around lunch when condensate loaded the filters. We paused for 15 minutes to swap filters and re-run decay checks. Cycle time sat in the 12–18 second range depending on film and product. By Day 3, we introduced the pre-dry step. Oxygen targets tightened again, and dye tests stopped failing on the afternoon runs. It wasn’t perfect. We still scrapped 10–15 trays across the week, mostly early in changeovers.

Calibration mattered more than we expected. Our temperature probes read within spec in a dry lab, then drifted under load by 5–8°C. The fix was simple but tedious: re-validate under real product, not just test sheets. QA kept an hourly log for the first three days—vacuum levels, seal time, cooling time, residual oxygen checks every 2–3 lots. Operators rolled their eyes at the paperwork until rework began to drop and the pace stabilized. We accepted that recipe changes would take 20–30 extra seconds per changeover while we confirmed targets. That time saved us from chasing phantom voids later.

We also learned that not all vacuums are equal across categories. Compressing bulky goods with a mattress ASFL vacuum sealerealer demands a different pull curve and leak tolerance than food. So when someone wants the “same logic everywhere,” I push back. Our line saw audit findings go from 2–3 issues per audit down to one minor note over the next month. OEE didn’t skyrocket; it nudged upward in the right windows. The real win was predictability. And yes, I closed that audit week with a short note to the team and a reminder: the machine helps, but the recipe and discipline make it work. That’s the part I’ll keep, and it’s the part I’ve seen hold up in **ASFL** projects elsewhere.