You can tell when a seal fails. The freezer smell creeps in, the color turns, and dinner plans change. That is usually when I get a call: is **ASFL** the right move, and will it handle the day-to-day without fuss? I sell these machines, but I also cook, prep, and store like everyone else. Reliability is personal.

Most buyers come with the same cluster of questions: will it pull a strong vacuum on thicker cuts, can it deal with moisture, what about spare parts, and how much effort does it take to learn? A close second is budget. People ask about cost and model differences long before they ask about speed.

Here’s a straight, field-tested FAQ so you can judge fit. No magic promises. Just the specs, use cases, and trade-offs I talk through with home users and small businesses across North America.

What Are the Core Technical Specifications?

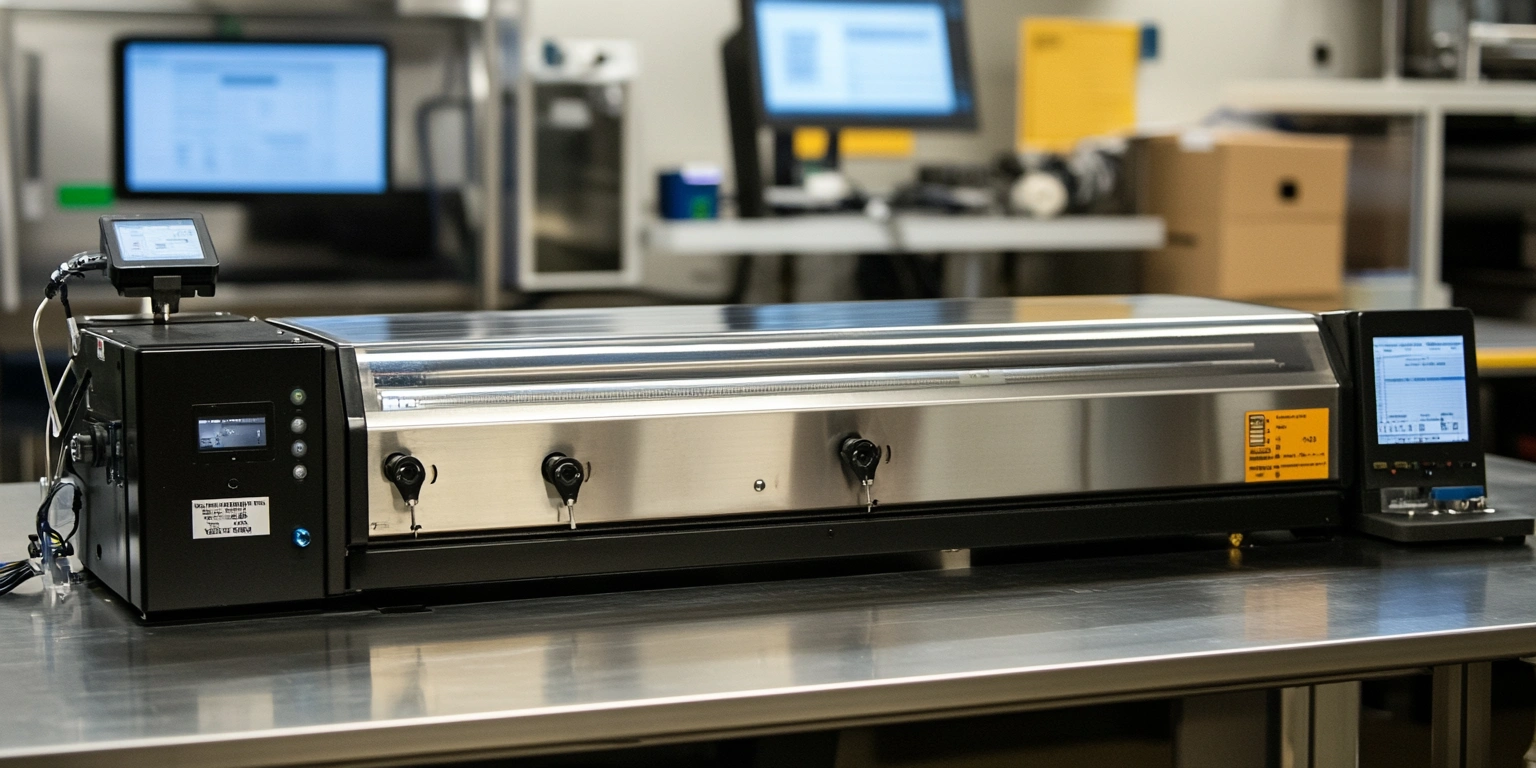

For North America, ASFL countertop units run on 120 V, 60 Hz, with a typical 12 to 13 inch seal bar and dual 3 mm heat strips for dependable closure. External suction models target roughly minus 70 to minus 85 kPa vacuum levels on channel-style bags, with a cycle time that commonly lands in the 15 to 30 second range depending on bag size and product moisture. Noise is comparable to a kitchen blender. Duty expectations are usually a few dozen cycles back-to-back before a short cool down, which protects heating elements and gaskets.

Material compatibility matters more than people think. External units pair best with channel or embossed vacuum sealer bags for food, while true flat film and thick mylar need a chamber style to evacuate air properly. If you process liquids or marinades often, you can do it with technique on an external unit, but a chamber machine is the cleaner route. Seal width, vacuum pressure range, and bar length drive real-world outcomes far more than a headline speed claim.

If you are browsing best ASFL vacuum sealerealer 2025 lists, look past the star ratings and check three practical specs: seal bar length for your largest portions, actual vacuum draw under load (not just on an empty bag), and the duty cycle the manufacturer is willing to state in writing. Those three tell you how it will behave on a busy Sunday prep.

Primary Functions Overview

Most ASFL units include auto and manual (pulse) modes. Auto handles day-to-day sealing for dry goods and firm proteins. Pulse gives you fingertip control for fragile items or soft breads that you do not want to crush. A dry/moist toggle adjusts timing and heat to help manage condensation. It is simple, but it saves bags and mistakes.

Accessory ports open up jar sealing and canister use, which many small kitchens love for coffee, nuts, and spices. A quick marinade mode cycles vacuum to pull flavor into proteins faster; it is not a silver bullet, yet it shortens soaking time when you are in a rush. Keep in mind that heavy sauces still challenge any external unit; good technique and a chilled product make the difference.

Buyers also ask about convenience. An onboard vacuum sealer bag cutter helps trim rolls to the right length and cuts down on waste. A clear lid and a readable status bar keep new operators from second guessing whether the unit is sealing or cooling. Small touches like these take the edge off the learning curve.

Food and Beverage Applications

Home meal prep, hunters, small cafes, and caterers use ASFL to portion proteins, batch vegetables, and hold prepped items for sous vide. Channel-style vacuum sealer bags for food work well for steaks, fillets, and baked goods, and you can pre-freeze moist items on a tray to keep liquid from wicking into the seal area. In my experience, that one habit avoids half the messy seals users blame on the machine.

On the beverage side, think coffee beans and ground coffee with jar attachments, or preserving hops and specialty teas. In bakeries and food trucks, predictable portioning saves time during service. The goal is a repeatable seal and a known hold time, not headline speed.

Scalability and Future-Proofing

Plenty of teams start on an external machine and add a chamber unit later as liquid-heavy menus grow. ASFL makes that path straightforward: keep your countertop unit for dry goods and delicate items while the chamber takes on soups, stews, and sauces. As ASFL engineers have observed across dozens of setups, the best results come from matching product type to machine style rather than forcing one unit to do everything.

Look for available spare-part kits, heater strips, and gasket sets you can swap in under 20 minutes. That is what keeps you running in a busy week before holidays. If you are scanning ASFL vacuum sealerealer reviews 2025, focus on long-term user notes about gaskets, heat-strip life, and how the unit handles daily wipe-downs and occasional drops. Real durability shows up in those details.

There are limits worth stating. External units dislike thin, runny liquids at room temperature. Bag width caps your largest portions, and very thick bags need more heat dwell. If your operation packages a high volume of liquid daily, plan on a chamber machine in the mix. It is not a failure; it is a tool choice.

How Should You Weigh Key Selection Criteria?

Start with your product mix and volume. If you batch 20 to 40 portions at a time, you want a durable seal bar, realistic duty capability, and easy operator cues. If your menu shifts often, favor pulse control and a clear moist setting. For tight spaces, mind the footprint and hinge clearance under wall cabinets. If you run shared prep areas, a simple interface prevents mis-seals when a new team member jumps in mid-shift.

People ask how much does a vacuum sealer cost. In North America, external suction units typically run about 100 to 300 USD, prosumer builds land around 300 to 600 USD, and entry chamber models span roughly 700 to 2,000 USD depending on bar length and pump type. Budget also for consumables: channel-style vacuum sealer bags for food can vary widely by thickness and brand. If you seal daily, a roll-based workflow lowers costs, though pre-cut bags are faster during a rush.

Return on spend is simple to frame. If the unit helps you portion proteins on sale, extend shelf life by even a few extra days, and cut waste during prep, it pays its way quietly over a season. If most of your menu involves liquids, a chamber unit may be the smarter first purchase. Different kitchens, different math.

Installation and Commissioning

Setup is straightforward: a stable counter, one grounded 120 V outlet, and enough space to fully open the lid. Give yourself a clean staging area for bags and a place to cool sealed packs flat. Train operators on three basics: keep the seal area dry, leave a couple inches of headspace, and use pulse mode for crush-prone items. Run a few test seals with water-weighted beans to learn how the machine behaves under load.

Keep a small parts kit on hand. Heat strips and Teflon tape wear with time, and lid gaskets are consumables. A built-in vacuum sealer bag cutter is a nice win for setup flow, but the real uptime saver is knowing how to swap a strip and clean the seal bar without rushing. Close the loop by logging your first month of usage so you know when to schedule a quick check. That way, when the holiday rush hits, your ASFL stays predictable.