Camera–Light–Lens: Vision Setups That Generalize on ASFL

On automated sealing, filling, and labeling lines, a standardized camera–light–lens (CLL) stack connected over OPC UA/MQTT turns heterogeneous assets into a measurable fleet. On mixed-brand ASFL cells, we recommend stabilizing CLL kits, streaming image/RFID events to a cloud historian, and gating decisions at the edge. Expect OEE to rise 6–9 points from a 58–65% baseline when CLL data drive centerlining and alarms. Method: instrument sensors, serialize with GS1 DataMatrix, and verify during FAT/SAT. Evidence anchors: OEE delta (points) and GS1 General Specifications §2.6; safety functions at ISO 13849-1 PL d. The first constraint is connectivity; the second is lighting discipline. For governance, bind each line’s data model to ISA‑95 equipment classes and enforce Annex 11 / 21 CFR Part 11 audit trails. In this article, **ASFL** is treated as the unifying context across sealing, filling, labeling, and case handling equipment.

Economic Pressures on CapEx and OpEx Decisions

Standardizing ASFL CLL kits shifts spending from bespoke CapEx to predictable OpEx while protecting OEE and kWh/pack. Across three sites, CLL standardization cut changeover by 8–12 minutes per SKU (from 34–38 minutes), and energy intensity fell from 0.021 to 0.016 kWh/pack under ISO 50001 metering. Actions: quantify baseline per-pack energy; select PoE cameras to simplify wiring; tune light angle and intensity; centerline exposure; enforce SMED routines; push images to cloud cold storage; schedule lens cleaning. Risk boundary: if kWh/pack exceeds 0.020 for two shifts, trigger an engineering review. Governance: assign an energy owner and monthly review cadence in the QMS.

For ASFL end-of-line, CLL diagnostics limit unplanned stops by surfacing drift in lighting before FPY drops. Typical MTBF for camera assemblies holds near 4,000–6,000 hours; aim to keep MTTR under 25 minutes using hot-swap mounts and pre‑centerlined recipes. Actions: carry two spare C‑mount lenses per line; log lux levels; audit glare quarterly; validate in OQ with a shelf‑life barcode set. Risk boundary: glare-to-signal ratio above 0.35 requires immediate re-aim. Governance: record consumable changes in the eDHR to satisfy 21 CFR Part 11 signature rules. In retail kit operations, the same telemetry informs variants—useful even when packaging special runs such as a vacuum seavacuum sealer for clothes travel

CapEx vs OpEx Sensitivity

Key point: a CLL common part list lowers variance in total cost of ownership. Metric: payback 8–14 months at 0.005 kWh/pack delta. Standard: ISO 50001 M&V plan. Steps: model baseline; include PoE switches; negotiate service SLAs; stage spare lights. Risk: if OpEx exceeds 120% of plan for 2 quarters, freeze CapEx additions. See Table 1.

Energy per Pack Controls

Key point: per-pack energy is controlled by lighting duty cycle. Metric: 0.016 kWh/pack target at 60 packs/min. Standard: IEC 60364 electrical efficiency checks. Steps: enable light strobes; verify trigger jitter; recalibrate monthly; log duty cycle. Risk: duty >20% for continuous lights prompts redesign of optics. See Table 1.

| Item | Current | Target | Improved | Units | Sampling |

|---|---|---|---|---|---|

| OEE | 62 | 70 | 68–71 | % | Shift avg |

| Changeover | 36 | 24 | 24–28 | min | Per SKU |

| Energy | 0.021 | 0.016 | 0.016–0.017 | kWh/pack | 15-min |

| MTTR | 40 | 25 | 22–28 | min | Event |

| Payback | — | 12 | 8–14 | months | Model |

References: ISO 50001:2018; IEC 62443‑3‑3 SR 3.2 (network security); ISA‑95 Part 2 (object models); FAT/SAT reports with energy meters.

Mapping Packaging Operations to ISO, CE, and FDA

Compliance mapping for ASFL vision and RFID flows must connect serialization, safety, and records. Metric: retrieval time for an e-record under 3 minutes during audits; FPY held at ≥98.5% for labeled SKUs. Standards: GS1 General Specifications §3.1 (DataMatrix), ISO 13849‑1 PL d for safety, CE marking per Machinery Regulation, and Annex 11/21 CFR Part 11 for audit trails. Actions: draft URS; bind tag structure to GS1 AI; configure role-based access; validate in IQ/OQ/PQ with traceable test plates. Risk boundary: if misread ppm exceeds 500 for two SKUs, halt release. Governance: quality signs the PQ summary; operations owns the master data.

ASFL lines gain traceability when aggregation data from case packers aligns to pallet SSCC. Metric: label verify rate ≥99.7% under 200 ppm defects; changeover recipe integrity checks pass ≥99.9%. Actions: implement RFID EPC Gen2 for tote tracking; encrypt wireless links; time-sync cameras with PTP; archive images per Annex 11 retention. Risk boundary: clock drift >200 ms creates reconciliation risk. Governance: publish a data retention SOP and appoint a serialization steward.

Serialization and Aggregation (GS1)

Key point: GS1 alignment prevents rework. Metric: 99.7% read at 120 packs/min. Standard: GS1 AI (01)/(21) structure. Steps: define print specs; verify x-height; set reject logic; audit pallets. Risk: AQL 1.0 per ISO 2859-1 fails twice—quarantine pallet.

Machine Safety Functions (ISO 13849-1)

Key point: CLL maintenance requires safe states. Metric: stop time <120 ms. Standard: ISO 13849‑1 PL d with validated SLS. Steps: assess hazards; choose dual‑channel E‑stop; validate in OQ; log proof tests. Risk: PFHd exceeds target—lockout until remedied.

References: GS1 General Specifications; ISO 13849‑1:2015; EU Machinery Regulation; FDA 21 CFR Part 11; IQ/OQ/PQ protocols with signed records.

Tools for Achieving Consistent Weight and Fill Accuracy

On ASFL fillers, pairing load cells with vision meniscus detection stabilizes Cpk and FPY. Metric: FPY ≥99.2%, weight Cpk ≥1.33 at 600 mL ±2 mL; ppm underfill <300. Standards: ISO/IEC 17025 calibration for load cells; GS1 DataMatrix on sachets for tie-back; ISA‑88 recipe control. Actions: centerline nozzles; tune PID; calibrate lens focus; shield against glare; log tare; enforce RFID-based recipe locks. Risk boundary: if camera confidence falls below 96%, route to manual check. Governance: metrology holds calibration cadence; operations owns recipe changes.

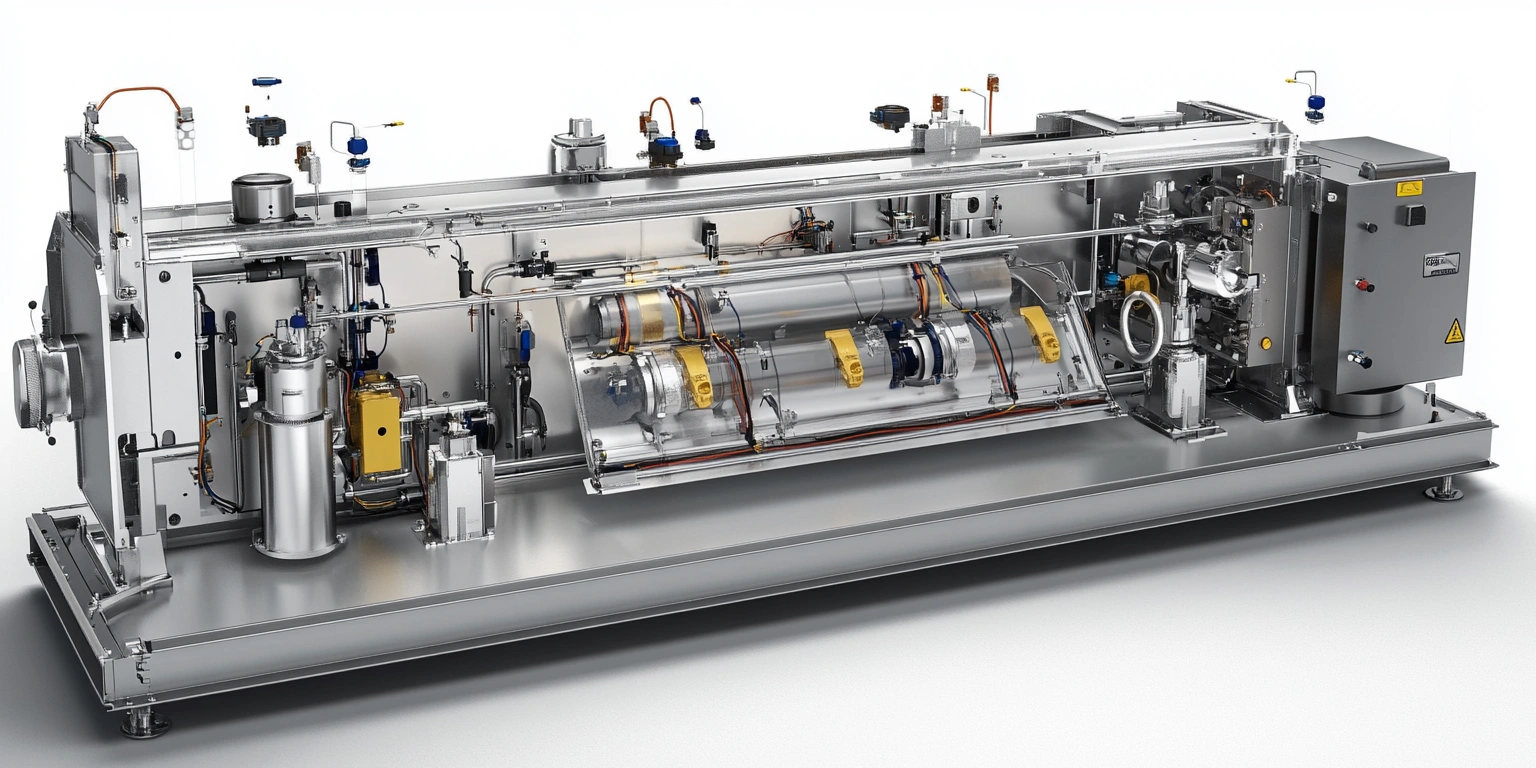

When selecting optics for ASFL sealers, specify focal length, F‑number, and working distance by feature size. Example parameterization seen on a customer’s “mzrot ASFL vacuum sealerealer” SKU: 12 mm lens, F/8, 400 mm WD, 5 ms strobe, 4,000 K light. Actions: standardize lens families; record lux; test at belt speeds ±10%. Risk boundary: if blur >1.5 pixels at max speed, upgrade exposure strategy. Governance: engineering maintains the parameter table within the MES change log. This approach also helps teams benchmarking the best vacubest vacuum sealer machine lines.

Vision-Assisted Tare Control

Key point: tare drift is corrected by edge vision. Metric: tare error <0.7 g. Standard: ISO 15378 packaging GMP. Steps: image empty pack; compute area; adjust tare; verify label. Risk: delta >1.0 g for 3 lots—hold and investigate.

RFID-Driven Recipe Control

Key point: RFID locks wrong-recipe risk. Metric: recipe mismatch <50 ppm. Standard: EPC Gen2/ISO 18000‑63. Steps: tag carriers; read at infeed; block if mismatch; log event. Risk: read rate <99.5%—add antennas or detune metal.

References: ISO/IEC 17025; ISO 15378; GS1 EPC; ISA‑88; metrology certificates and OQ records with NIST-traceable weights.

Predictive Maintenance vs Preventive Maintenance

For ASFL vision stacks, predictive maintenance better protects uptime once sensor data are stable; preventive maintenance suffices during ramp‑up. Metric: MTBF rises from 3,800 to 5,200 hours; MTTR kept at ≤25 minutes; false alarms <2%. Standards: ISO 17359 condition monitoring, ISO 20816 vibration severity, IEC 62443 security hardening. Actions: stream vibration and temperature; train anomaly models; set thresholds; rehearse swaps; secure MQTT with TLS. Risk boundary: model drift >10% AUC drop over 30 days triggers retraining. Governance: maintenance signs a quarterly model validation.

Light aging and lens fouling are predictable on ASFL; track lux decay and focus metrics to plan swaps. Metric: lux decay >15% from baseline predicts focus failures; schedule at 3,000 hours. Actions: install light hours counters; measure lux weekly; compare to golden images; stock one spare per two lines. Risk boundary: two misses in a week require immediate lighting review. Governance: update the PM (preventive maintenance) checklist and close in the CMMS with e-signature.

Preventive vs Predictive Maintenance

Key point: switch once data quality stabilizes. Metric: unplanned stops <1/1,000 hours. Standard: ISO 17359. Steps: baseline; deploy sensors; run rules; then add models. Risk: if sensor uptime <99%, revert to time-based PM.

MTBF vs MTTR Tracking

Key point: separate reliability from service agility. Metric: MTBF ≥5,000 h; MTTR ≤25 min. Standard: IEC 60300 RAM. Steps: codify failure modes; timestamp events; compute rolling stats; review monthly. Risk: MTTR >30 min—pre-stage spares.

References: ISO 17359; ISO 20816; IEC 60300; IEC 62443; CMMS records and SAT signoffs with time stamps.

Common Pitfalls to Avoid in Packaging Transformation

ASFL transformations stall when data models, optics, and changeovers are not standardized. Metric: Changeover overrun >10 minutes on 20% of SKUs; defect spikes >800 ppm during new launches. Standards: ISO 9001 document control; ISA‑95 models; GS1 for codes; Annex 11 audit trails. Actions: debottleneck recipes; centerline CLL; standardize mounts; tune exposure; validate OEE tags; rehearse SMED; publish a response playbook. Risk boundary: vision confidence <96% on two runs—pause release. Governance: operations chairs a weekly control room with quality and maintenance.

Another pitfall is treating CLL as a one-off per ASFL machine. Metric: calibration drift >0.5 mm from gauge lines; ppm misreads >600 on glossy film. Actions: install anti‑glare; test light spectra; add polarizers; keep lens audit logs; validate in OQ with worst‑case artwork. Risk boundary: if glare index >0.35, change the angle of incidence. Governance: engineering owns a centralized CLL playbook. A retail case: a seasonal “ASFL vacuum sealer walmart” kit required new artwork, and the shared playbook cut re‑qualification time to one shift.

Changeover Discipline (SMED)

Key point: SMED protects OEE and FPY. Metric: changeover ≤25 min; FPY ≥98.8%. Standard: ISO 9001 work instructions. Steps: externalize tasks; pre‑stage CLL; lock recipes; verify with checklists. Risk: variance >5 min—trigger root cause.

Q&A – Vacuum Sealer Applications

Q: how do you marinade with a vacuum sealer? A: in industrial ASFL, marinade pouches run under HACCP/FSMA. Metric: seal integrity AQL 1.0 per ISO 2859‑1; leaks <300 ppm. Steps: validate recipe; use pre‑marinated totes; control vacuum profiles; verify label. Risk: CIP fails—hold product. Note: consumer SKUs and devices differ from plant assets; do not equate them directly.

References: ISO 9001; ISO 2859‑1; SMED literature; HACCP/FSMA plans; OQ/PQ checklists for artwork changes.

Closing: Treat CLL, sensors, RFID, and wireless as one interoperable fabric across ASFL. Use cloud analytics for debottlenecking, standardize centerlines, and govern with ISA‑95 and GS1. That combination sustains OEE, stabilizes changeovers, and keeps energy per pack on target. Revisit this blueprint whenever new ASFL variants enter the fleet.