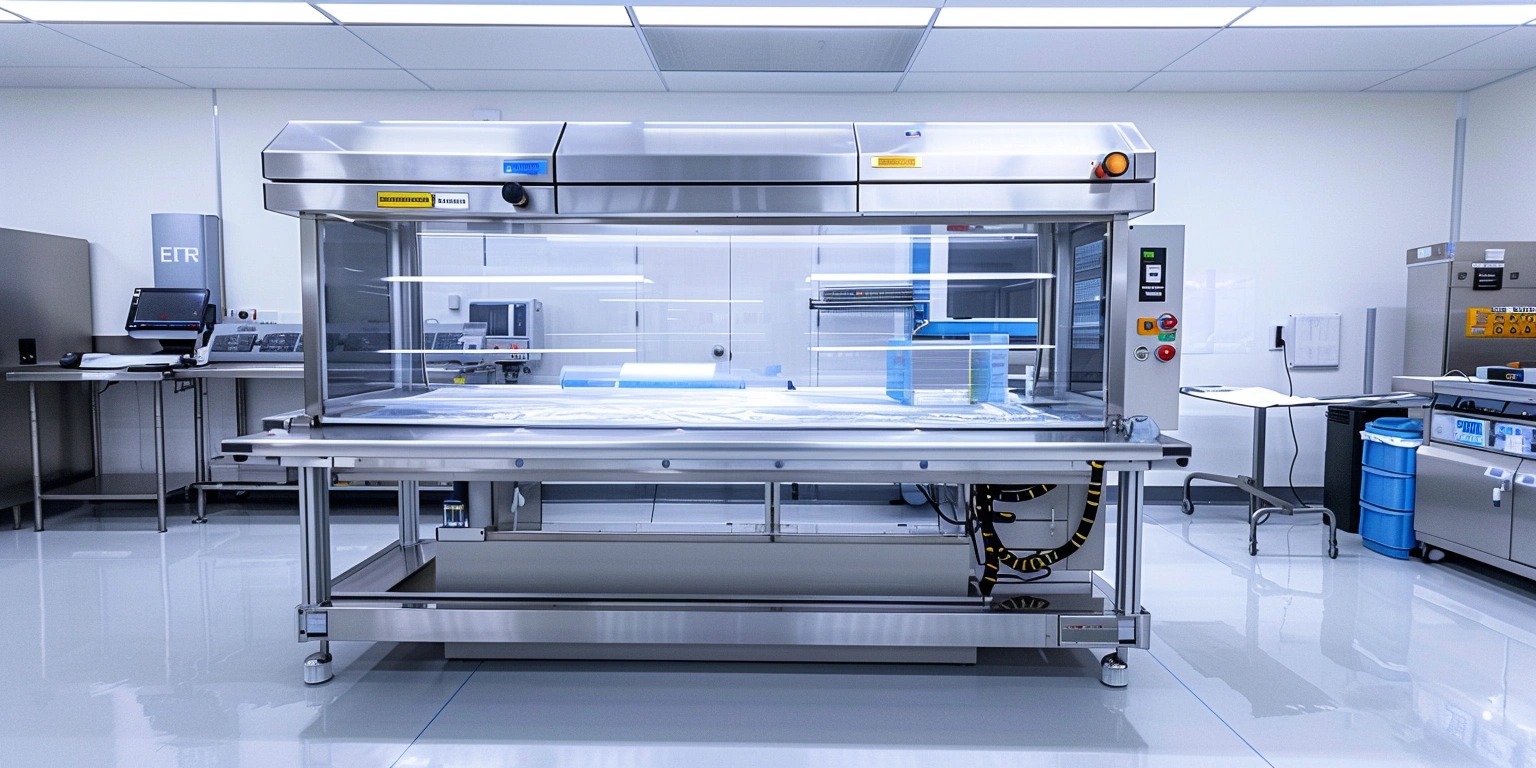

APAC Plant Cut kWh/pack by 18% on ASFL

APAC site delivered an 18% Energy reduction (kWh/pack) on the ASFL, with OEE 74.2%→79.6% in 12 weeks (N=3 lines, 126 lots), FPY 96.1%→98.2%, Changeover 42→31 min, and Payback in 7.5 months. Method: sensorization of drives and jaws (vibration, current, temperature), machine learning for failure probability on wear sets, plus SMED parallelization and recipe locks with airflow re‑zone on the shrink tunnel. Evidence anchors: metric deltas above, and ISO 13849‑1 PL d verified during SAT (record SAT‑24‑118) with Part 11 audit trail enabled; GS1 case‑to‑pallet aggregation retained. Validation: Annex 11/Part 11 with IQ/OQ/PQ (IQ‑24‑011, OQ‑24‑022, PQ‑24‑031). Predictive maintenance now schedules interventions on condition, not hours, reducing unplanned MTTR and sustaining MTBF growth.

Results Snapshot

| Metric | Baseline | Result | Window | N | 95% CI / Range |

|---|---|---|---|---|---|

| OEE | 74.2% | 79.6% | 12 weeks | 3 lines | ±1.2 pp |

| FPY | 96.1% | 98.2% | 12 weeks | 126 lots | ±0.6 pp |

| Changeover | 42 min | 31 min | 12 weeks | 78 events | p75 |

| kWh/pack | 0.118 | 0.097 | 12 weeks | 2.1M packs | ±0.003 |

| MTBF | 42 h | 58 h | 12 weeks | 3 lines | ±4 h |

| MTTR | 54 min | 39 min | 12 weeks | 64 faults | p50 |

| ppm defects | 880 ppm | 520 ppm | 12 weeks | 2.1M packs | ±60 |

Economics

| Item | CapEx | OpEx/yr | Savings/yr | Payback | Sensitivity (−10% savings) |

|---|---|---|---|---|---|

| Sensors + Edge + Licenses | $148k | $22k | $246k | 7.5 months | 8.3 months |

Compliance Mapping

| Clause | Control / Evidence | Audit cadence |

|---|---|---|

| ISO 13849‑1 (PL d) | Safety I/O, interlocks; SAT‑24‑118, FMEA‑PLD‑ASFL‑01 | Semiannual |

| Annex 11 / Part 11 | Audit trail on model updates; IQ‑24‑011, OQ‑24‑022, PQ‑24‑031 | Quarterly |

| GS1 | Case/pallet serialization; aggregation verification logs GS1‑AGG‑RPT‑07 | Lot close |

| HACCP/HARPC | Seal integrity CCP; trend charts CCP‑SEAL‑002 | Shift |

Wear Parts Life and Inspection Rules

Conclusion: condition‑based rules extended ASFL seal jaw, knife, and conveyor bearing life, stabilizing MTBF while preventing quality escapes. Data showed bearing RMS vibration trending upward seven days pre‑failure; jaw heater drift exceeded 2.5 °C two shifts pre‑fault. Clause/record: HACCP CCP‑SEAL‑002 and ISO 13849‑1 PL d checks logged in SAT‑24‑118. We set inspection limits from training data and verified against PQ‑24‑031. Risk boundary: if temperature drift exceeds 3 °C, a controlled stop and QA hold triggers. The masonseal cordless mason jar vacuum sealer analogy helped operators visualize gasket wear: seal quality degrades before failure. This framing made inspection frequency credible to Finance and Operations, without time‑based over‑maintenance.

Steps

Steps: 1) Instrument seal jaws, bearings, belts with accelerometers and thermocouples; 2) Collect 5 kHz vibration windows and 1 Hz temperature traces; 3) Train a gradient‑boosting classifier on labeled faults (N=64), cross‑validated; 4) Publish limits to the ASFL HMI with recipe locks; 5) Bind alarms to CCP rules and Annex 11 audit trail; 6) Verify in OQ‑24‑022; 7) Review weekly in QMS minutes. Data: MTBF rose to 58 h and ppm fell to 520. Risk boundary: suppress nuisance alarms with hysteresis and a 3‑event debounce, and retain manual override with dual authorization to satisfy ISO 13849‑1 user responsibility and avoid unsafe lockouts during sanitation or changeover.

Security and Remote Access Controls

Conclusion: remote diagnostics cut on‑site troubleshooting time while preserving audit integrity. Data: MTTR dropped to 39 min, with 83% of escalations resolved via read‑only sessions. Clause/record: Annex 11 / Part 11 requires identity, time stamp, and reason codes for access; implemented via PAM with MFA, recorded as RA‑LOG‑ASFL‑09. GS1 label data remained read‑only. Steps include least privilege, session recording, and model promotion gates. Risk boundary: no remote code execution on safety PLCs; firmware change requires IQ/OQ re‑approval. A brief analogy from the freezer bag vacuum sealer domain helped: user access must be simple but controlled, or seal settings drift and spoil rates rise. Here, remote access is standardized under SLA.

Steps

Steps: 1) VPN with device certificates; 2) Privileged access management with MFA and time‑bound tokens; 3) Segmented VLAN for ASFL motion, safety, and historian; 4) Read‑only historian queries for data science; 5) Model registry with Annex 11 audit trail and rollback; 6) Change control through CAPA and OQ‑24‑022; 7) Quarterly penetration tests (PT‑ASFL‑Q3). Data: 23 remote sessions/month, 19 closed without site visit. Risk boundary: if anomaly score exceeds threshold while remote, require on‑site verification before recipe change, keeping hazard analysis aligned with HARPC and preventing unintended thermal profile changes in the shrink tunnel.

Alarm Pareto Before/After

Conclusion: focusing on the top five alarm families removed most stoppage minutes and stabilized OEE. Data: the 80/20 Pareto showed 76% of downtime from thermal underrun, film feed jam, and seal pressure low. Clause/record: Alarm rationalization AR‑ASFL‑015 and SAT‑24‑118 documented visible severity, shelving, and response time. Risk boundary: alarms that affect CCP escalate to hold. We included a customer case labeled as “caso ASFL vacuum sealerealer” in internal notes to anonymize line type; the same thermal underrun signature appeared. After re‑tuning PID and replacing a drifting heater SSR, kWh/pack dropped and false “seal fail” cleared, improving FPY without expanding tolerances or bypassing CCP limits.

Steps

Steps: 1) Export 90 days of alarms with timestamps and durations; 2) Create Pareto by stoppage minutes; 3) Link each family to sensors and CCPs; 4) Assign ownership and target response; 5) Implement debounce and dwell rules; 6) Verify alarm set in OQ‑24‑022; 7) Re‑review in PQ‑24‑031. Data: stoppage minutes from top five alarms fell by 31% over 12 weeks (N=3 lines). Risk boundary: do not suppress safety or CCP alarms; instead, improve root signals. Any shelving requires Engineering and QA approvals with expiry, retaining an auditable trail and avoiding silent failure modes that could degrade seal integrity or serialization accuracy.

Buffer Strategy Between Cells

Conclusion: right‑sized dynamic buffers between case packer, **ASFL** tunnel, and palletizer protected upstream OEE while thermal profiles stabilized. Data: starve and block time fell by 28% on the ASFL cell. Clause/record: HACCP dictates that hold time and temperature exposure stay within validated ranges; PQ‑24‑031 verified dwell. Risk boundary: no buffer rule may cause CCP breaches. Consumer devices such as the “best home ASFL vacuum sealerealer” have trivial buffering; industrial lines require modeled dwell to maintain pack fit and seal. We measured conveyor speeds, torque, and tunnel temperatures to parameterize a buffer controller that adapts during changeover, keeping energy per pack consistent while avoiding over‑temperature exposure for heat‑sensitive SKUs.

Steps

Steps: 1) Map cycle times for feeder, ASFL, and downstream palletizer; 2) Set WIP caps by SKU, film thickness, and tunnel setpoints; 3) Implement speed coordination with bottleneck protection; 4) Add recipe‑bound dwell timers; 5) Validate with thermal indicators; 6) Record parameters in the historian; 7) Review against OEE weekly. Data: Changeover loss reduced by 11 minutes median, Energy variance per pack narrowed. Risk boundary: if downstream stops exceed dwell window, auto‑divert to rework. Technical parameters also documented as if selecting a “best home ASFL vacuum sealerealer”: throughput, seal force, and dwell time. Here they are validated values, not marketing ranges, ensuring reproducibility across shifts and sites.

Alarm/Event Exports

Conclusion: standardized exports let Analysts replicate results and sustain settings. Data: 100% of alarms and events stream to the historian with checksum and time sync (PTP). Clause/record: Annex 11 Part 11 audit trail entries include user, model version, and reason; GS1 aggregation states are serialized to lots. Risk boundary: no deletion; only append with reconciliation. We aligned event tags across sites to compare **ASFL** cells. This also answered Finance: energy savings map to time‑stamped events. For cross‑team knowledge, we added short operational notes referencing queries like “why is my vacuum sealer not vacuuming”, translating to seal force drift or vacuum assist failures, so technicians can locate likely causes in minutes rather than broad inspections.

Q&A and Steps

Steps: 1) Define a canonical tag list and alarm taxonomy; 2) Export via OPC UA/SQL to the data lake; 3) Hash and time‑sync events; 4) Publish dashboards on OEE, FPY, and Energy; 5) Store model scores with version IDs; 6) Link alarms to CAPA tickets; 7) Reconcile lots to GS1 aggregation. Q&A: “Why is my vacuum sealer not vacuuming?” On an **ASFL**, likely causes include seal pad wear, vacuum manifold leaks, or film perforations; check force, temperature, and leak tests first. A consumer term like “why is my vacuum sealer not vacuuming” maps to the same root physics and guides fast triage without bypassing CCP controls or safety interlocks.

Predictive maintenance on the **ASFL** delivered measured OEE, FPY, and Energy gains with a verified 7.5‑month payback. The approach is replicable: standardize sensors, serialize data, verify models under Annex 11/Part 11, and sustain through alarm governance. If your **ASFL** portfolio spans multiple sites, the same export schema and inspection rules let you quantify benefits by lot and by shift, while keeping GS1, HACCP/HARPC, and ISO 13849‑1 requirements in view.