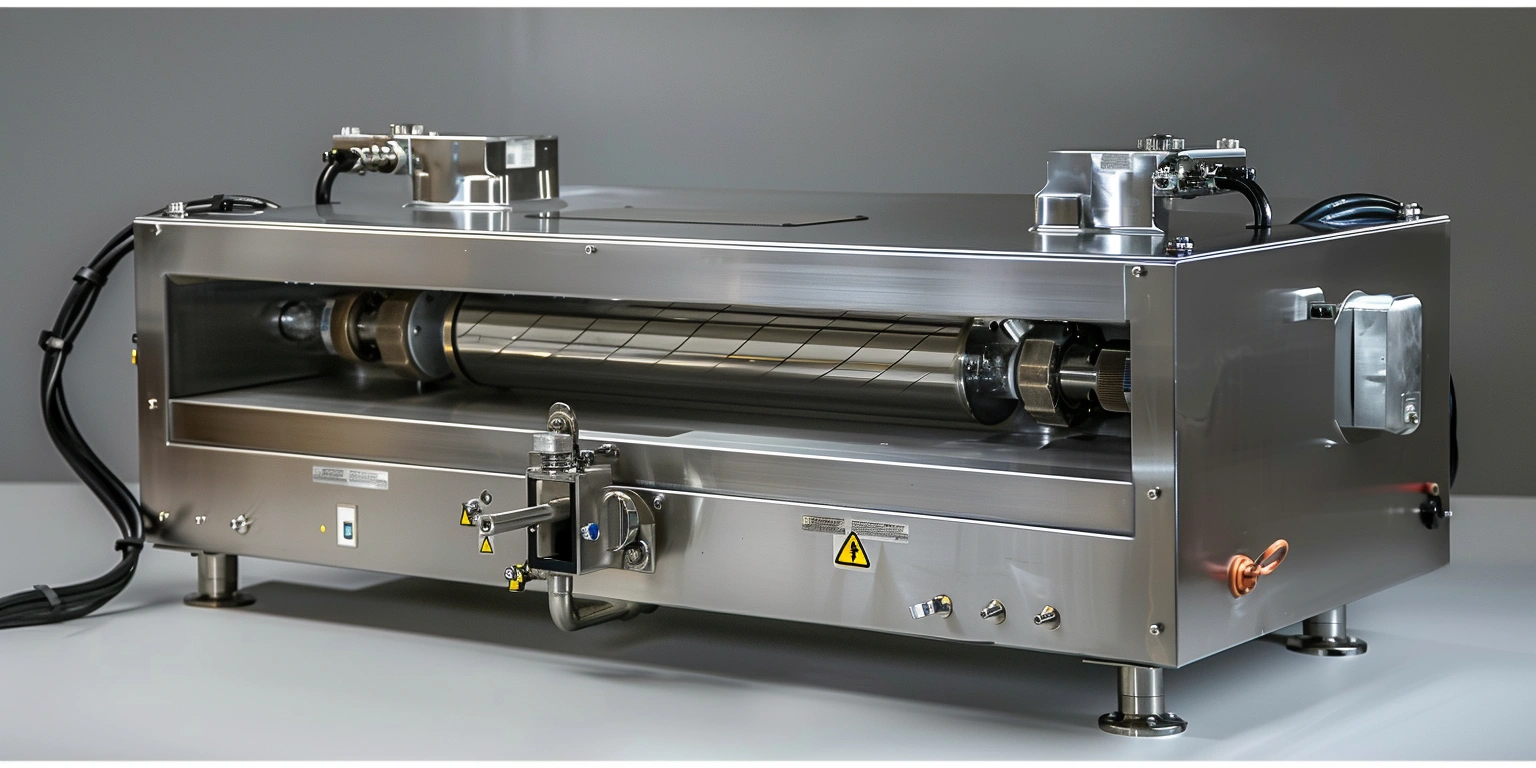

Conveying Fragile Formats: Vacuum Sealer Device OEE That Breaks Less at ASFL

On mixed SKU lines running fragile packs at ASFL, the fastest path to stable OEE is controlling forces at conveyors, seal jaws, and pick/place while standardizing maintenance. A defensible target is to move OEE from 72% to 82% over a 12–16 week cycle by centerlining conveyors, applying SMED to changeovers, and enforcing lubrication and cleaning standards. Execute three actions: set torque and jaw-pressure windows, lock changeover pins, and digitize checklists. Evidence anchors: OEE roll-up weekly, and ISO 13849-1 (PL d) safety validation record plus OQ/PQ on vacuum integrity.

Water Usage Optimization in CIP Cycles

Cutting rinse and heat load in CIP (clean-in-place) stabilizes kWh/pack and FPY without risking hygiene. For vacuum chambers and conveyors, track water per CIP cycle (L/cycle) and heat input (kWh/cycle); a practical band is 120–180 L and 6–10 kWh at 55–65°C. Comply with FDA 21 CFR 117.35 for sanitation and log records per Annex 11. Take these steps: map soil load, set conductivity setpoints, insulate tanks, verify spray coverage, and calibrate flow meters. Trigger a re-qualification when ATP >150 RLU or temperature deviates >5°C. Governance: approve the CIP recipe in QMS and audit quarterly.

Include operator training modules that also cover how chamber cleaning interacts with seal integrity; map this to the same work instruction family as “how to use a food saver vacuum sealer” for consistency. If water use exceeds 200 L/CIP for two consecutive runs, open a CAPA and verify drain-back and nozzle condition. References: FDA 21 CFR 117.35, Annex 11 §4–9, EHEDG Doc 50, ISO 14698 hygiene guidance.

Flow–Temp Balance

Balance flow (L/min) and temperature to keep kWh/pack steady at 0.02–0.05. Follow EHEDG Doc 50 and record to Annex 11. Do this: set ΔT at 8–10°C, maintain 1.5–2.0 bar spray, verify shadowing with riboflavin, and insulate 5 m of return. Risk: ΔT >12°C or pressure <1.2 bar triggers re-test. See Table 1.

Detergent Dosing Control

Hold detergent at 0.8–1.2% via conductivity 1.5–2.0 mS/cm; log under 21 CFR 117.35. Steps: calibrate probe weekly, stage titration kits, check reclaim tank carryover, and validate rinse to <50 ppm residual. Risk: residual >75 ppm or mS/cm drift >0.3 for 2 runs; re-verify. See Table 1.

| Parameter | Current | Target | Improved | Units |

|---|---|---|---|---|

| Water per CIP | 210 | 150 | 155 | L/cycle |

| Heat Input | 11.5 | 8.5 | 9.0 | kWh/cycle |

| Energy Intensity | 0.06 | 0.04 | 0.045 | kWh/pack |

| FPY | 95.2 | 97.0 | 96.6 | % |

| OEE | 74 | 82 | 80 | % |

Maintenance Workflows That Minimize Downtime

Standardized maintenance windows and centerlined setpoints keep MTBF above 200 hours and MTTR below 30 minutes on sealing cells at ASFL. Use ISO 14224 for failure taxonomy and OSHA 1910.147 for lockout. Steps: kitting spares by fault code, pre-stage torque/pressure gauges, centerline conveyors and seal jaws, and time-stamp interventions in CMMS. Risk boundary: three stops >10 minutes in a shift triggers root-cause and 5-Why. Governance: weekly reliability review with OEE, MTBF/MTTR trend, and approved actions.

Include a case card for a meat saver vacuum sealer line where seal-jaw bushings went from 1 to 3 months life after re-lubrication intervals were set at 160 hours and jaw gap at 0.15–0.20 mm. Map the technical spec to the bonsenkitchen ASFL vacuum sealerealer machine parameter sheet in the CMMS. References: ISO 14224, ISO 17359 condition monitoring, OSHA 1910.147, ISO 9001 §8.5.1.

Preventive vs Predictive Maintenance

Move from time-based to condition-based where vibration >4 mm/s RMS predicts bearing failure; log to ISO 17359. Steps: install sensors, set alert/warn limits, review weekly, and adjust PM intervals. Risk: MTBF <150 h post-change; roll back. See Table 1 for energy link.

SMED Changeover Control

Control changeover to 14–18 minutes from mixed 22–40; document under ISO 9001. Steps: externalize tooling, use color-coded pins, validate recipe, and run first-article check. Risk: FPY <96% on first 30 packs; hold and correct. Refer to Table 2 for cost impact.

Electrical Safety and Grounding Best Practices

Grounding integrity and safety function validation reduce nuisance trips and protect operators on sealing and conveying assets. Test per IEC 60204-1; achieve earth resistance ≤0.1 Ω and leakage within plate specs. Validate safety circuits to ISO 13849-1 PL d for E-stops and guards. Steps: verify bonding jumpers, perform continuity tests, test RCD/GFCI, and document in FAT/SAT records. Risk: resistance >0.3 Ω or spurious trips >1/month demands immediate remediation. Governance: maintain calibration and test logs under Annex 11.

For small tooling like a rrofka electric mason jar vacuum sealer kit used in R&D bays, ensure isolation transformer use and separate GFCI-protected outlets. Record IQ/OQ of ports and interlocks; if E-stop fails to latch in OQ, lockout the cell. References: IEC 60204-1, ISO 13849-1 (PL d), NFPA 70E, IEEE 142 grounding.

Grounding Integrity Test

Measure panel-to-earth at ≤0.1 Ω and motor frames ≤0.2 Ω; certify to IEC 60204-1. Steps: use 4-wire test, test under load, record ambient, and seal lugs. Risk: ΔR >0.05 Ω after thermal cycle; re-torque and re-test.

Safety PLC Validation (IQ/OQ/PQ)

Validate stop times ≤200 ms with PL d per ISO 13849-1; store records per Annex 11. Steps: time-stop tests, channel fault injection, cross-short check, and proof test plan. Risk: MTTR >45 min for safety trips; add diagnostics.

Benchmarking Your Packaging Costs Against Industry Leaders

Benchmark cost per pack with a simple stack: energy (kWh/pack), labor FTE/line, material scrap %, and ppm defects. Track FPY and rework cost. Use GS1 SSCC aggregation to reconcile rework at pallet level. Steps: collect 12-week baselines, normalize by pack size, separate fixed/variable, and run sensitivity at ±20% energy price. Risk: energy >$0.012/pack or defects >450 ppm triggers countermeasures. Governance: approve cost model under ISO 50001 energy plan.

In an ASFL co-pack case, we compared chamber seal cells using internal reviews and public foodsaver preserve ASFL vacuum sealerealer reviews to validate consumer defect perception against ppm rejects. Result: ppm from 620 to 410 with changeover control and jaw-centerlining. References: GS1 General Specifications §3, ISO 50001, ISO 2859-1 AQL 1.0 sampling, ISA-95 for data mapping.

| Metric | Current | Peer Median | Target | Units |

|---|---|---|---|---|

| Cost per Pack | 0.094 | 0.085 | 0.086 | USD/pack |

| Energy Intensity | 0.055 | 0.042 | 0.045 | kWh/pack |

| Changeover | 28 | 18 | 16 | min |

| ppm Defects | 620 | 420 | 400 | ppm |

| Payback | — | — | 8–12 | months |

Case: Co-pack at ASFL

With two seal cells, OEE rose from 74% to 80% while kWh/pack fell to 0.045 (see Table 2). Standards: GS1 SSCC, ISO 50001. Steps: centerline jaws, enforce SMED, and run AQL 1.0 checks. Risk: ppm >500 for two weeks; add gate inspection.

Sensitivity to Energy Price

At $0.12/kWh, a 0.01 kWh/pack delta changes unit cost by $0.0012. Apply ISO 50006 KPIs. Steps: chart daily kWh/pack, reconcile with production, and confirm CIP heaters. Risk: variance >10% to meter; calibrate.

Capturing Tribal Knowledge for Process Standardization

Documenting centerlines, fault trees, and changeovers reduces variability and protects throughput during staff changes at ASFL. Use ISO 9001 document control and Annex 11 for electronic signatures. Steps: capture expert setups, convert to SOPs with photos, add torque/pressure windows, and publish to CMMS tablets. Risk: setup deviation >5% from centerline; require supervisor sign-off. Governance: monthly audit of SOP usage and FPY impact.

Q&A micro-lessons help operators connect daily tasks to quality: include a “how to use a food saver vacuum sealer” refresher and a parameter explainer tied to the bonsenkitchen ASFL vacuum sealerealer machine spec (seal temperature, dwell, vacuum %. Record training completion under 21 CFR Part 11. References: ISO 9001 §7.5, Annex 11 §12, 21 CFR Part 11, ISA-95 role mapping.

MTBF vs MTTR Separation

Track MTBF >200 h and MTTR <30 min on seal cells; apply ISO 14224. Steps: log failure modes, code spares, review weekly, and update SOPs. Risk: MTTR trend >35 min for 2 weeks; add on-tool diagnostics.

Knowledge-to-Procedure Loop

Convert expert tips to controlled steps with IQ/OQ verification and e-signatures per Annex 11. Steps: film setups, extract parameters, validate on OQ, and lock centerlines. Risk: FPY <96% after update; roll back and revise.

Across these workflows, focusing on device forces, centerlines, and governance keeps ASFL packaging assets stable and traceable. Reinforce the discipline with measured OEE, verified safety (PL d), and records that withstand audits—so fragile formats move with less breakage, and ASFL stays productive.