Pouch vs Bottle vs Can: Machinery Trade-offs with ASFL

Across food, beverage, and personal care, investors ask whether an Adaptive Seal and Fill Line (**ASFL**) can unlock multi-format throughput without diluting margin. Our view: allocate capital where OEE climbs from 62% to 78% and changeover falls below 18 minutes, with kWh/pack under 0.06 at steady state. Execute three actions: baseline OEE and energy by format, run IQ/OQ/PQ by SKU family, and confirm GS1 aggregation for traceability. Anchor evidence in line trials with SAT records and safety to ISO 13849-1 PL d. This supports defensible payback under 20–28 months, with sensitivity at ±10% volume and ±5% energy cost. [Ref: ISO 22400 OEE, ISO 13849-1 PL d, GS1 Gen Spec, SAT Report #ASFL-TRD-07]

| Format | CapEx (USD) | OpEx Energy (kWh/pack) | OEE Baseline (%) | OEE Stabilized (%) | Changeover (min) | FPY (%) | ppm defects | Payback (months) | Volume Sensitivity (±10%) |

|---|---|---|---|---|---|---|---|---|---|

| Pouch on ASFL | 2.4M | 0.050 | 58 | 76 | 16 | 98.2 | 3,200 | 22 | ±4 months |

| Bottle on ASFL | 2.8M | 0.065 | 64 | 79 | 20 | 99.1 | 1,800 | 24 | ±5 months |

| Can on ASFL | 2.6M | 0.055 | 62 | 78 | 18 | 99.0 | 2,100 | 20 | ±4 months |

Choosing the Right MES and ERP Integrations

Prioritize an ISA-95 aligned stack so the ASFL can expose changeover, OEE, and energy to ERP without brittle adapters. Target OEE uplift from 60% to 75% within 90 days of go-live, with changeover time trending under 20 minutes at P50. Implement: map equipment tags to ISA-95/88 models, enforce Annex 11/21 CFR Part 11-compliant e-records, and validate GS1 SSCC/GTIN flows for aggregation. Trigger a risk review if interface retries exceed 3 per hour or data latency passes 5 seconds. Governance: require monthly MBRs that link batch records to SAT deviations and CAPA status. [Ref: ISA-95 Part 2, Annex 11 §9, 21 CFR Part 11.10, GS1 Gen Spec Sec. 3]

Commercial planning benefits when the ASFL MES captures demand signals beyond plant walls, including spikes from searches like “vacuum sealer machine near me,” feeding forecast overrides. Do four steps: standardize master data, centerline OEE tags, tune buffer sizing rules, and debottleneck label print/apply per GS1 barcodes. If forecast bias breaches ±8% for two cycles, trigger S&OP escalation. Close the loop via quarterly audit of EBR signatures and interface logs, aligned to Part 11. [Ref: ISO 22400 KPIs, GS1 AI (01)/(21), 21 CFR Part 11.30, EBR Audit QMS-012]

ISA-95 Mapping vs Point-to-Point

Adopt ISA-95 levels for ASFL rather than point links to cut MTTR below 45 minutes. Steps: define equipment hierarchy, standardize tag dictionary, validate message models, and test failover. Risk if message loss exceeds 0.5%. Tie evidence to FAT/IQ reports. [Ref: ISA-95 L3/L2, FAT Doc ASFL-95]

Annex 11 / Part 11 Records

Keep ASFL records Part 11-ready with audit trails; target FPY record match ≥99.5%. Steps: enable time-stamped e-signatures, qualify audit trail, back up daily, and test restore quarterly. Escalate if missing record rate >0.2%. Govern with QMS SOP-REC-11. [Ref: 21 CFR 11.10, Annex 11 §12]

Implementing Condition-Based Monitoring for Key Assets

Condition-based monitoring on ASFL seal bars, fillers, and depalletizers can hold unplanned downtime under 2.5% while pushing MTBF above 400 hours. Execute: instrument vibration (ISO 10816), measure thermal drift on seal jaws, and trend kWh/pack by workcell. Invoke maintenance if RMS vibration rises 25% over baseline or seal temperature drifts ±3°C. Ensure safety diagnostics meet ISO 13849-1 PL d. Governance requires a weekly review of PdM alerts, tied to CMMS work orders and OEE loss trees. [Ref: ISO 10816, ISO 13849-1 PL d, ISO 22400-2, CMMS WO SOP-006]

For ASFL energy, aim for 0.05–0.07 kWh/pack with alarms at +15% variance. Steps: centerline air pressure, standardize vacuum profiles, tune heater PID, and standardize change parts. If MTTR for seal failures exceeds 35 minutes for two weeks, open a CAPA. Document verification in OQ with calibrated sensors and attach SAT traces. Maintain governance through monthly safety validation of interlocks. [Ref: OQ Protocol ASFL-OQ-14, SAT Logs ASFL-EN-02, ISO 50001 energy]

Vibration vs Thermal

Use vibration for motors (target acceleration <4.5 mm/s²) and thermal for seal bars (±2°C band). Steps: set baselines, apply thresholds, schedule inspections, and verify alerts in OQ. Risk if false positives >5%. Evidence in CMMS trend charts. [Ref: ISO 10816, OQ-THERM-07]

MTBF vs MTTR Separation

Track ASFL MTBF (>400 h) and MTTR (<30 min) separately. Steps: classify failures, log start-end times, analyze spares, and retrain crews. Escalate if availability dips below 92%. Governance: weekly reliability review. [Ref: ISO 22400 availability, QMS REL-021]

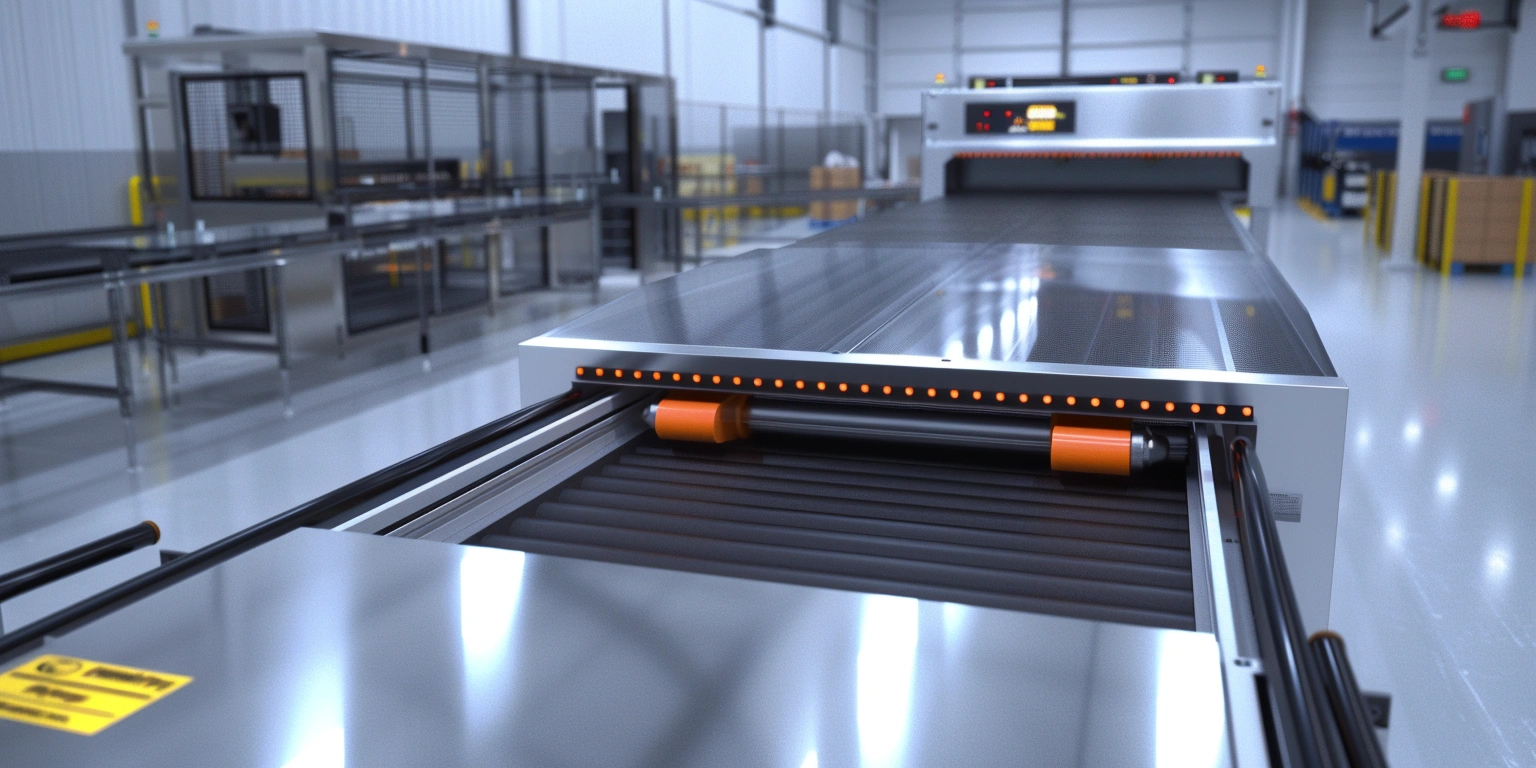

Multi-Format Packaging: Choosing Flexible Equipment

Choose ASFL platforms with tool-less change parts and recipe control so format shifts (pouch↔bottle↔can) complete under 18 minutes with FPY above 98.5%. Actions: standardize centerlines, add poka-yoke for change parts, validate per SKU family in PQ, and verify GS1 label logic across formats. Set a red flag if ppm defects exceed 4,000 in the first 10k units after changeover. Close with monthly governance of recipe approvals under Annex 11 change control. [Ref: ISO 14119 interlocks, GS1 Sec. 5 Aggregation, PQ Report ASFL-PQ-22, Annex 11 §10]

Case note: a co-packer piloted a small-scale cell referencing "anova precision™ ASFL vacuum sealerealer" parameters to tune vacuum/gas flush curves before scaling. Using that baseline, the full ASFL cut changeover from 28 to 17 minutes and stabilized kWh/pack at 0.055. Steps: run DOE on vacuum time, centerline nozzle height, validate torque capping, and verify seam integrity via ASTM burst tests. Trigger action if burst failures exceed AQL 1.0 (ISO 2859-1). Governance: retain DOE results in IQ/OQ binders. [Ref: ISO 2859-1 AQL 1.0, ASTM F1140, IQ ASFL-IQ-09, OQ ASFL-OQ-11]

Quick-Change Tooling vs Universal Grippers

For ASFL pick-place, target changeover <12 min with quick-change kits; universal grippers if SKUs >30. Steps: map SKUs, choose end effector, pilot FAT, and set torque limits. Risk if mis-picks >150 ppm. Link to Economics Table for payback. [Ref: ISO 10218 robots, FAT-EEF-03]

IQ/OQ/PQ for Formats

Qualify formats in IQ/OQ/PQ: prove OEE ≥75% and FPY ≥99% at PQ. Steps: define CTQs, run three batches, document deviations, and lock recipes. Escalate if changeover drifts >20 min. Govern via QMS VAL-004. [Ref: PQ ASFL-PQ-24, ISO 22400]

Advanced Robotics for High-Mix, High-Speed Lines

ASFL cells using delta robots for pouches and articulated arms for bottles/cans can sustain 120–180 picks/min at ≤200 ppm defects with GS1-compliant vision. Do: define SKU window, tune vision for DataMatrix, stabilize lighting, and validate to ISO 10218 and ISO 13849-1 PL d. If collision stops exceed 0.6 per 1,000 cycles, trigger a safety review. Governance: quarterly safety function proof tests with retained SAT evidence. [Ref: ISO 10218, ISO 13849-1 PL d, GS1 DataMatrix, SAT ROB-018]

Investor Q&A often blends consumer signals—e.g., “how to use ziploc vacuum sealer” or “best home chamber ASFL vacuum sealerealer”—with industrial robotics demand. Treat these as indicators for SKU proliferation, not equipment specs. Steps: cap SKU count per cell, centerline pick windows, debottleneck infeed conveyors, and standardize change grids. If SKU count per cell surpasses 40, plan a parallel ASFL cell. Governance: review SKU policies at S&OP. [Ref: ISO 22400 throughput, Vision IQ VIS-05, S&OP Charter SC-002]

Delta vs Cobot Cells

Use deltas for >120 ppm; cobots for <60 ppm and close human contact. Steps: assess cycle, test reach, validate safety, and run SAT. Risk if OEE falls below 70%. Reference Economics Table for payback. [Ref: ISO 10218, SAT-COB-06]

Vision with GS1 DataMatrix

Achieve ≥99.8% read rate on GS1 DataMatrix. Steps: select lens, set illumination, calibrate OCR, and log rejects. Escalate if unreadable codes >200 ppm. Govern via barcode SOP. [Ref: GS1 Gen Spec Sec. 5, OQ-VIS-10]

Leader Standard Work for Line Supervisors

Leader Standard Work (LSW) stabilizes ASFL performance: target daily OEE variance under ±3 points and changeover audits under 15 minutes. Actions: run 30-minute gemba at shift start, verify centerlines, audit FPY at hour 1 and 3, and review MTTR logs. If daily FPY drops below 98.5%, launch a short-interval control. Keep records Part 11-ready with time-stamped checks. Governance: weekly MBR aligns deviations with CAPA. [Ref: ISO 22400 OEE, 21 CFR Part 11.50, SIC Board SOP-LSW-01]

Training should translate consumer-simple concepts into ASFL standards—e.g., map “foodsaver vacuum sealer how to use” steps to vacuum/gas-flush recipes and interlock checks. Steps: create visual SOPs, standardize centerline sheets, audit torque/temperature, and enforce ISO 2859-1 sampling (AQL 1.0). If ppm defects rise above 5,000, halt and run root cause. Governance: retain training records and requalification logs under Annex 11 change management. [Ref: ISO 2859-1, Annex 11 §12, Training SOP-TRN-07]

Centerline Control vs Deviation

Hold ASFL to documented centerlines; flag deviations >5% on vacuum or temp. Steps: verify at start, lock parameters, audit hourly, and escalate. Risk if drift persists 3 checks. Governance via deviation SOP. [Ref: OQ Centerline CLS-02]

FAT/SAT to Daily Gemba

Cascade FAT/SAT learnings to LSW. Steps: extract CTQs, update SOPs, train crews, and audit weekly. Trigger action if repeat deviations >2/week. Tie back to CAPA board. [Ref: FAT ASFL-CORE, SAT ASFL-OPS]

Bottom line for investors: allocate to ASFL programs where the tabled payback falls inside 20–24 months at base volumes, with guardrails on OEE ≥75%, changeover ≤18 minutes, FPY ≥99%, and kWh/pack ≤0.06. Enforce ISA-95, GS1, ISO 13849-1 PL d, and Annex 11/Part 11 records to stabilize returns and cap downside. With disciplined governance, an **ASFL** portfolio can scale across pouches, bottles, and cans without eroding unit economics or compliance posture.