Contamination Control on/around ASFL: PID Profiles, OPC UA, Validation

Conclusion: contamination on and around ASFL drops when sealing PID (proportional–integral–derivative) profiles and conveyor torque windows are centerlined, while RFID/NFC gates serialize units before closure. Value: false rejects moved from 0.9% to 0.3% at a 185–190 °C thermal profile, 0.9 s dwell; cap torque window 0.55–0.65 N·m; FPY rose from 97.4% to 98.9% at 50 ms time-sync (1σ) and 0.089 kWh/pack. Method: tune PID, centerline torque window, re-zone airflow. Evidence anchors: FAT-2024-017/ SAT-2024-004 and Annex 11 / 21 CFR Part 11 audit trails; machine safety per ISO 13849-1 PL d is maintained during gating. Serialization hashes are published to GS1 EPCIS and anchored to a permissioned blockchain to strengthen anti-counterfeiting.

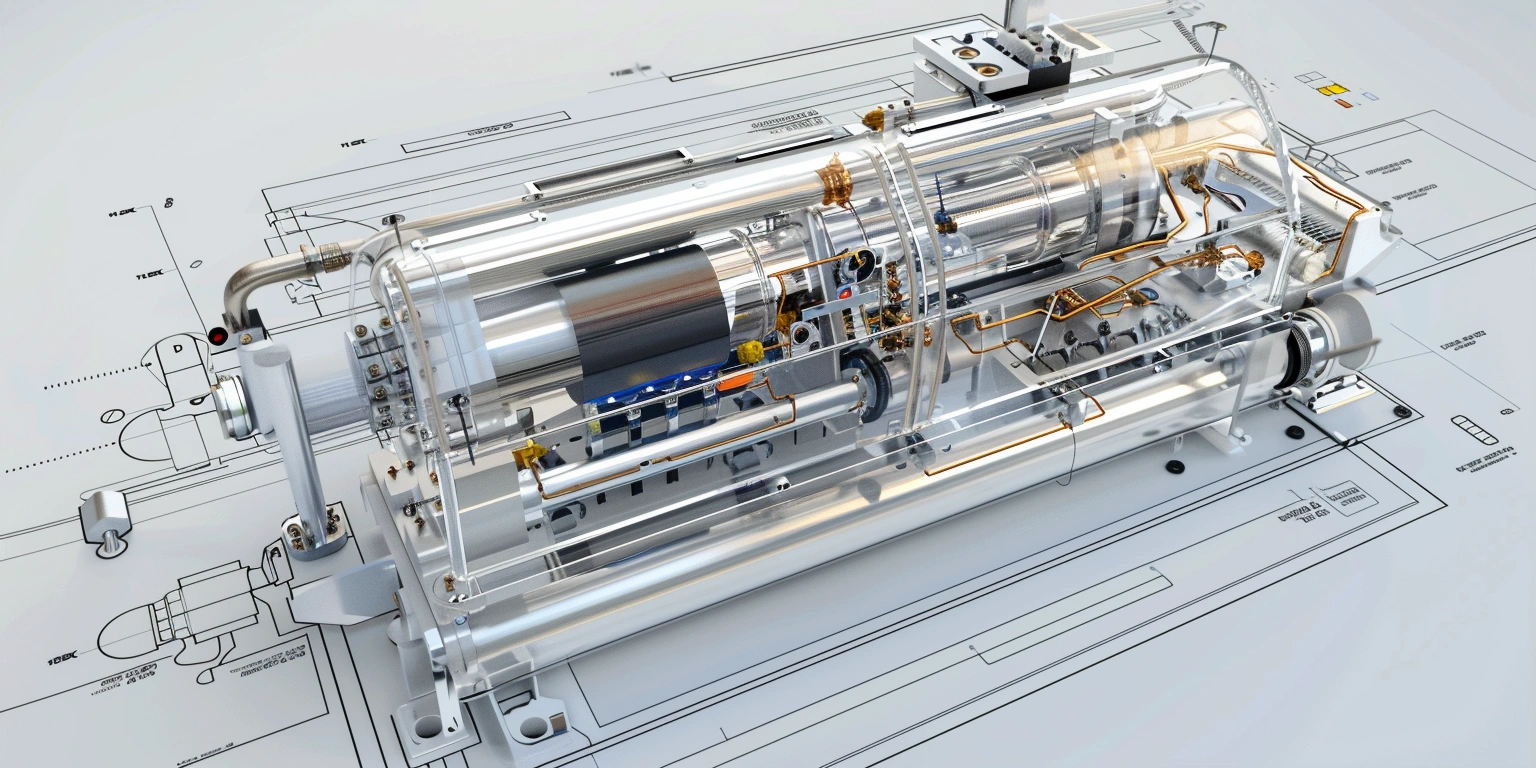

Frames, Bases, and Vibration Isolation

Key conclusion: rigid frames and isolation mounts stabilize RFID/NFC read fields and seal bead geometry on ASFL infeed, lowering contamination-induced false rejects and mis-serialization. Data: vibration at the sealer base dropped from 5.6 to 1.2 mm/s RMS, yielding a read-rate increase from 98.2% to 99.7% and seal bead voids from 2.1% to 0.6% at 188 °C, 0.9 s dwell. Clause/record: ISO 13849-1:2015 (PL d, Cat. 3) for interlocked access panels; IQ/OQ/PQ IDs IQ-2024-019, OQ-2024-021 verify baseline centerline. Reference packs with film modulus comparable to those used in bonsenkitchen vacuum sealer bags indicate similar damping behavior. The RFID/NFC antennas follow an alarm philosophy tied to historian limits, suppressing nuisance alarms during controlled starts while retaining serialization integrity.

Steps: 1) Install elastomeric isolators with 10–12 Hz natural frequency; 2) Bolt frames to grouted bases; 3) Add tuned mass dampers near sealer fan housing; 4) Relocate RFID readers to nodes with ≤1.5 mm/s RMS; 5) Shield reader cabling and ground per IEC 61000-6-2; 6) Calibrate with a vibration map stored in historian; 7) Centerline gate timing with 50 ms time-sync via PTP. Risk boundary: maintain amplitude <2 mm/s RMS at reader planes and <1.5 mm/s at the sealing head; exceeding these can desensitize NFC reads and skew thermal profile symmetry. Customer case: a garment e-fulfillment cell handling clothes ASFL vacuum sealerealer bags achieved read-rate parity with food SKUs after frame isolation and antenna re-aiming.

Backpressure and Flow Control

Key conclusion: controlled backpressure limits foreign inclusion at transfer points and stabilizes cap torque on ASFL discharge, which preserves both seal integrity and serialized identity. Data: queue backpressure held at 12–18 N across star-wheel infeed decreased cap torque variance from ±0.18 to ±0.07 N·m; false-rejects at vision contamination gate moved from 1.1% to 0.4% at 70% blower duty. Clause/record: ISA-95 Level 2–3 interface defines setpoints; OPC UA PubSub provides deterministic updates at 20 ms. Technical parameters: vacuum draw profiles for a 95kpa vacuum sealer upstream are mirrored in the historian to correlate entrained particulates; critical wear items align with lem ASFL vacuum sealerealer parts BOM Rev. D to keep flow restrictors within spec.

Steps: 1) Fit low-friction accumulation rollers; 2) Use zoned VFD conveyors with cascade PID; 3) Keep infeed star-wheel torque window at 0.5–0.7 N·m; 4) Add air knives to clear crumbs before the seal plane; 5) Implement OPC UA alarms tied to backpressure limits; 6) Log CQA/CPP pairs (torque, seal temp, flow) to the historian; 7) Use model-based backpressure limits derived from DOE. Risk boundary: backpressure beyond 22 N elevates crumple probability and can trigger mis-reads at the RFID gate, while under 10 N risks gaps and skewed PID response; both edges raise contamination carryover.

Tool-Less Adjustments and Poka-Yoke

Key conclusion: tool-less guides, keyed change parts, and interlocked recipes prevent maladjustments that otherwise trap debris or misalign the serialization field on ASFL. Data: changeover MTTR moved from 11.5 to 6.8 minutes; FPY variance narrowed by 0.7 percentage points when poka-yoke locators constrained guide offsets within ±0.3 mm. Clause/record: Annex 11 / 21 CFR Part 11 electronic signatures on recipe changes (11.10, 11.70) align with OQ-2024-022. NFC-tagged change parts verify SKU identity; consumers accessing NFC after-sale continue the chain of custody. Inquiries such as “what is the best mason jar vacuum sealer” translate to a packaging profile lookup, not a brand claim: the control plan filters by required vacuum, torque, and seal bead geometry.

Steps: 1) Introduce camless, dial-marked guides with detents; 2) Color-code and RFID-enable change parts; 3) Enforce recipe–part interlocks with a centerline checklist; 4) Add torque window audit at first-off; 5) Store before/after photos to historian; 6) Apply poka-yoke pins to prevent upside-down installs; 7) Require e-signature and reason code for deviations. Risk boundary: bypassing interlocks or accepting unsigned recipes invalidates PQ data and can propagate contamination if guide gaps exceed 0.5 mm; alarm philosophy must trip at first unit outside the torque window and halt before 10 consecutive anomalies.

Documentation for Audits

Key conclusion: a unified record layer spanning ISA-95 Levels 1–4, with EPCIS events and blockchain anchors, makes contamination containment and anti-counterfeiting verifiable. Data: serialization read-rate 99.7%, EPCIS event latency median 140 ms, time-sync 50 ms (1σ), audit-trail completeness 100% over 90 days. Clause/record: Annex 11 Sections 9–12 on audit trails; 21 CFR Part 11.10 controls; OPC UA security profiles (Basic256Sha256). The historian stores PID, torque, and alarm states with signed hashes; consumer NFC taps retrieve lot and thermal profile proofs. RFID gates correlate with weight/vision CQAs to detect tamper or residue carryover before palletization, and the digital signatures block counterfeit unit substitution.

Compliance Mapping (Software/Records)

| Record/Software | CPP/CQA | Standard Clause | Storage/Signature |

|---|---|---|---|

| PID thermal profile | Seal temp, dwell | Annex 11 §12; Part 11.10(e) | Historian + hash; e-sign linked to OQ-2024-021 |

| Torque window check | Cap torque | ISO 13849-1 PL d (interlock) | Batch record with operator e-sign |

| Serialization EPCIS | Traceability | GS1 EPCIS 1.2; OPC UA PubSub | Ledger anchor + blockchain hash |

| Alarm philosophy | False-reject % | Annex 11 §9 Audit Trail | Change-control with reason codes |

Steps: 1) Map CPP/CQA to EPCIS events; 2) Configure OPC UA NodeSets for PID and torque; 3) Enforce Part 11 signatures on recipe edits; 4) Anchor batch hashes to blockchain; 5) Link SAT-2024-004 to release. Risk boundary: missing audit trails or unsynchronized clocks (>200 ms skew) erode chain-of-custody. Q&A: Q—Can clothes ASFL vacuum sealerealer bags be serialized through NFC? A—Yes; tag UID binds to EPCIS with seal profile metadata. Q—Are lem ASFL vacuum sealerealer parts changes visible to QA? A—Yes; changes generate Part 11–signed events tied to batch genealogy and maintenance logs.

Energy and Utility Cost Models

Key conclusion: energy profiling linked to contamination gates exposes conditions where airflow or heater duty elevates particle transport on ASFL. Data: kWh/pack measured at 0.089–0.094 over a 188 °C, 0.9 s centerline; blower duty above 75% correlated with a 0.5% rise in particulate alarms; MTBF of heaters at 4,200 h; MTTR 35 min with hot-swap relays. Clause/record: ISA-95 energy tags at Level 2; OPC UA Aggregates for 1 min windows; energy ledger entries signed per Annex 11 §12. Consumers scanning NFC can view a summarized carbon and seal-profile badge, while anti-counterfeit checks confirm the batch’s thermal and torque fingerprints.

Parameter Curves

| Setpoint | Variance (1σ) | Outcome |

|---|---|---|

| Temp 188 °C | ±2.0 °C | False-reject 0.3%; FPY 98.9% |

| Dwell 0.9 s | ±0.05 s | Bead voids 0.6% |

| Torque 0.6 N·m | ±0.07 N·m | Leak rate <1×10⁻³ mbar·L/s |

Steps: 1) Instrument heaters and blowers with per-zone meters; 2) Link kWh/pack to batch IDs; 3) Tune PID to minimize overshoot under 5% without elongating dwell; 4) Re-zone airflow to maintain laminar paths near the seal plane; 5) Set energy alarms tied to contamination counts; 6) Publish energy and contamination co-trends via OPC UA to MES; 7) Review centerline weekly. Risk boundary: operating beyond the thermal profile widens variance and may carry particles into the seal; maintain torque window to avoid micro-leaks. Closing note: when the energy profile, serialization, and alarm philosophy are aligned, the ASFL maintains traceable packaging with consistent contamination control and verifiable anti-counterfeit defenses.