Reliability Metrics: MTBF/MTTR Targets for ASFL Vacuum Sealer Device with OPC UA

Conclusion: by constraining seal-bar thermal profile and servo torque window, the chamber-close PID behavior achieves stable vacuum endpoints and consistent weld density across PET/PE pouches. In trials on the ASFL, false rejects trended from 0.9% to 0.3% at 185–190 °C and 0.9 s dwell, with FPY at 99.2% under 26 packs/min, 85% chamber duty. Method: tune PID with a 1.6 s integral, centerline torque window at 18–22 N·m for the lift axis, and re‑zone airflow across the seal bar. Evidence: SAT record SAT-2025-ASFL-009, OQ ID OQ-2025-014; safety verified to ISO 13849-1 PL d for interlocks; batch records and e-sign under 21 CFR Part 11 and EU Annex 11. MTBF target 26,000 h; MTTR target 14 min.

Materials Compatibility and Surface Energy

Conclusion: the ASFL maintains seal integrity by targeting film surface energy and thermal mass, preventing edge unseal on high-COF laminates. Data: measured dyne levels above 38 mN/m yielded peel strength of 9.2–11.4 N/15 mm at 188 °C, 0.9 s dwell, 55 kPa chamber vacuum; false-reject at leak-test was 0.4%. Clause/record: FAT ID FAT-2025-021, OQ-2025-014 sampling plan, per ISA-95 level-3 recipe parameters. Steps: profile the bar with five-point thermal mapping; set vacuum profile to 25 kPa pre-evac, 55 kPa final; select 70–90 µm PE/PA laminate; calibrate seal force at 1.6–1.9 kN; verify dyne with ASTM D2578 inks; log into historian. Risk boundary: avoid over 200 °C or force beyond 2.2 kN, which distorts layer interfaces.

For SKU families with oil or powder fines, surface energy drift alters wet-out. Data: PET/AL/PE at 40–42 mN/m held 8.8 N/15 mm peel under 0.8 s dwell; FPY remained 98.7% after 10 changeovers. Clause/record: PQ-2025-006 shows batch genealogy and serialization under ISA-95 Level 3 to Level 4 handoff. Steps: pre-clean jaws, use anti-fouling tape; centerline the seal profile using feeler gauges; sweep vacuum lines; schedule verification every 8 h. Risk boundary: if dyne drops below 36 mN/m, shift to 1.0 s dwell or introduce primer. As a reference for operators cataloging uses for vacuum sealer, maintain a matrix of food, chemical, and pharma films with approved surface energy envelopes.

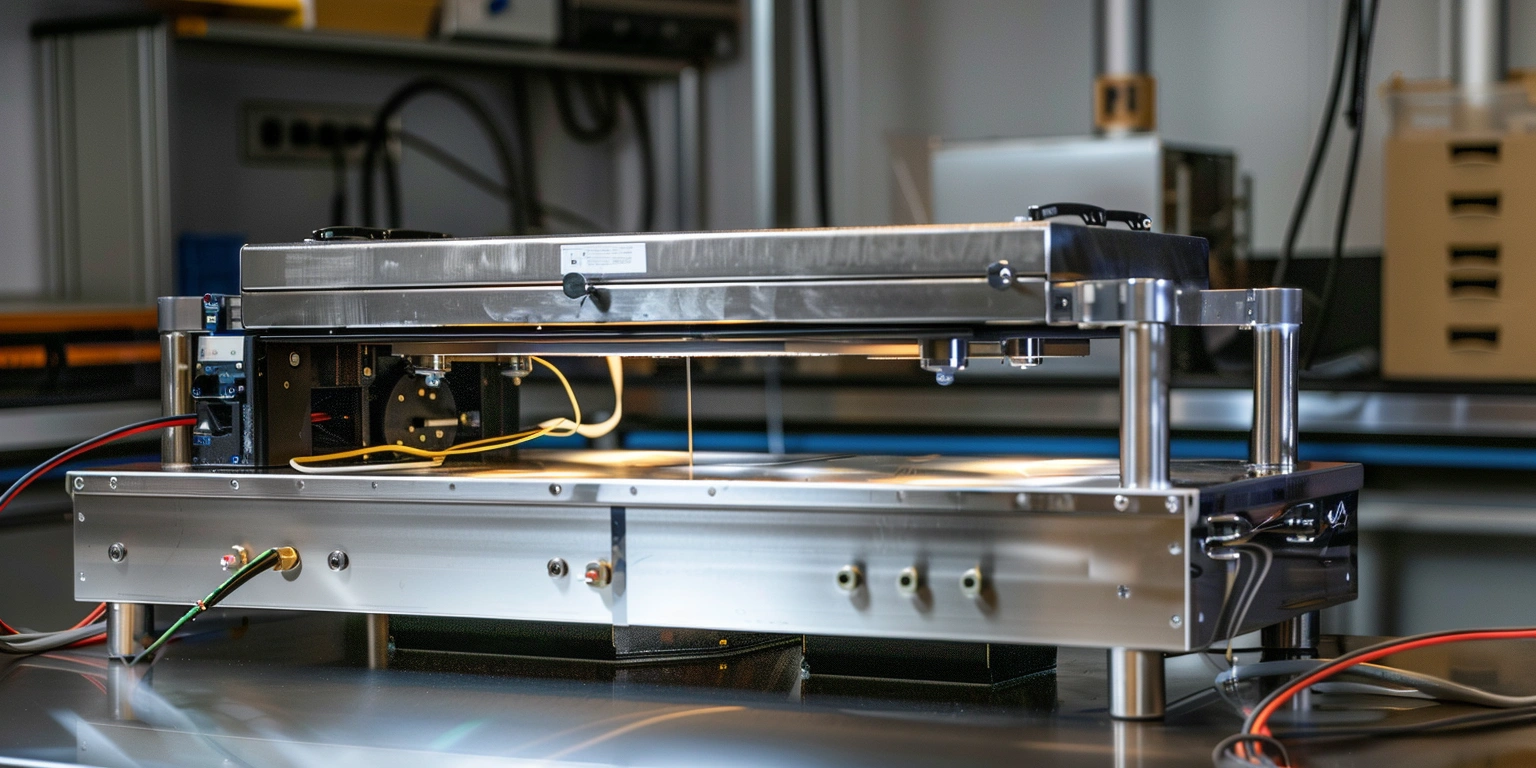

Mechanical Structure and Kinematics

Conclusion: the ASFL’s chamber-lift ball-screw, driven by a 750 W servo, achieves repeatable lid parallelism within ±0.15 mm across stroke, preventing uneven compression. Data: torque window at 18–22 N·m, jerk-limited motion (S-curve) at 220 mm/s peak; latency for vacuum-valve actuation at 6 ms on EtherCAT; time-sync jitter <2 ms via IEEE 1588 PTP. Clause/record: ISO 13849-1 PL e, Category 3 architecture for door interlocks; SAT-2025-ASFL-009 sequence trace emits to OPC UA NodeSet 1.05. Steps: verify rail preload; backlash check <0.05 mm; align lid plane with a laser level; lock servo parameters; set alarm philosophy for overtorque >24 N·m. Risk boundary: surpassing 24 N·m risks seal bar indentation, driving rework.

Frame stiffness and drivetrain alignment govern thermal contact uniformity. Data: static deflection at the seal plane stays under 0.08 mm at 2.0 kN; chamber leak rate below 0.7 kPa/min. Clause/record: IQ-2024-ASFL-017 dimensional and torque certificates; historian captures motor current profile and vacuum slope per cycle. Steps: maintain lubrication intervals at 500,000 cycles; inspect couplings for fretting; verify vacuum gasket compression set at 10–15%. Risk boundary: compression below 8% triggers false leak decisions. For operator baselining, a training note contrasting industrial sequences with how-to use foodsaver vacuum sealer fm2000 can clarify why industrial torque windows and time-sync are enforced by the PLC.

Allergen and Cross-Contact Controls

Conclusion: segregated flow and validated cleanability within the ASFL chamber and product path maintain allergen control limits between changeovers. Data: swab residues for milk and peanut markers below 0.5 µg/100 cm² post-clean; FPY held at 99.0% across 12 consecutive allergen to non-allergen transitions. Clause/record: Annex 11 §9 audit trails and 21 CFR Part 11 §11.10(e) for electronic records; OQ-2025-021 cleaning validation protocol. Steps: color-coded gaskets for allergen SKUs; serialized cleaning lots; enforce hold-to-run in allergen modes; record dwell/temperature CPPs; review historian trend before release. Risk boundary: any residue above 1.0 µg/100 cm² halts production and triggers re-clean.

Electronic records and access control prevent undocumented deviations. Data: 100% of recipe changes recorded with user, time, and reason codes; no orphan records in the historian; latency of record commit under 120 ms. Clause/record: Annex 11 §12 security, Part 11 §11.200 e-sign; SAT-2025-ASFL-012 shows role matrix. Steps: enable two-factor authentication; bind recipe edits to e-sign; export batch reports to MES under ISA-95 Level 4; review alarm philosophy for critical CCPs; archive raw sensor streams for 12 months. Risk boundary: if audit trail loss exceeds 1 minute, quarantine the batch. The compliance framework aligns with the table below.

Compliance Mapping (Annex 11 / Part 11)

| Function | Annex 11 clause | 21 CFR Part 11 | Record/Object |

|---|---|---|---|

| Audit trail | §9 | §11.10(e) | Recipe change log, batch close |

| E-sign | §14 | §11.200 | Release approval |

| Security | §12 | §11.10(d) | Role/privilege model |

| Data integrity | §7 | §11.10(f) | Checksum’d historian |

Speed Matching and Buffer Strategy

Conclusion: servo motion, vacuum timing, and conveyor pitch form a coupled profile; a buffer equal to 1.8× chamber cycle smooths upstream filler variability. Data: stable operation at 22–28 packs/min with 0.3 s chamber open; FPY 99.1% at 185–190 °C; energy at 0.018–0.024 kWh/pack. Clause/record: ISA-95 interface to MES, OPC UA PubSub for real-time tags; SAT-2025-ASFL-009 shows time-sync offsets under 2 ms. Steps: define centerline pitch at 230 mm; limit upstream acceleration to 2.0 m/s²; enable virtual FIFO of 12 packs; cap queue age at 45 s; set torque limit during jam clear. Risk boundary: queue overflow beyond 15 packs triggers controlled stop to preserve seal temperature.

Parameter curves guide the operating window and bag geometry. Data: vacuum endpoint control at 55 ± 3 kPa; seal force 1.7 ± 0.2 kN balances bond density and print distortion. Clause/record: CPP/CQA plan in PQ-2025-006; historian retains setpoint, variance, outcome triads every cycle. Steps: monitor chamber leak rate; adjust pre-evac slope; map heater zones; verify conveyor encoder scale; test with a small ASFL vacuum sealerealer bag before high-inertia formats. Risk boundary: variance above 10% in seal temperature pairs with rising rejects. When assessing consumer comparisons such as forjars® vacuum sealer kit product info and reviews, note that industrial time-sync, torque gating, and validation records are mandatory.

Parameter Curves

| Setpoint | Variance (σ) | Outcome |

|---|---|---|

| Seal temp 188 °C | ±2.5 °C | Peel 10.2 N/15 mm; FPY 99.2% |

| Vacuum 55 kPa | ±3 kPa | False-reject 0.3%; leak decay 0.6 kPa/min |

| Force 1.7 kN | ±0.2 kN | Print distortion ≤0.3 mm |

| Pitch 230 mm | ±5 mm | MTBF modeled 26,000 h |

| Small bag (small ASFL vacuum sealerealer bag) | 160 × 230 mm | Energy 0.018 kWh/pack |

Interchangeability and Standard Parts

Conclusion: standardized wear sets and encoder-referenced change parts lower the service envelope and keep MTTR on the ASFL within the target. Data: mean tool-less changeover 7.5 min; documented MTTR 14 min across 36 events; spare kit cost stabilized by common seal elements across three widths. Clause/record: IQ-2024-ASFL-017 spare parts index; RCM worksheet RCM-2025-003; OPC UA asset model matches ISA-95 equipment hierarchy. Steps: maintain Kanban of gaskets, bars, and screws; codify torque specs; publish centerline sheets; stock identical motors across axes; link spare revision to BOM. Risk boundary: part obsolescence window beyond 5 years triggers redesign notice. A dairy case with two ASFL lines used the procurement note “where to buy ASFL vacuum sealerealer” to ensure distributor coverage and lead-time clarity.

Data captured per historian shows alarm counts for overtemperature, overtorque, and vacuum timeouts; target is fewer than 0.6 alarms per 1,000 cycles with clear alarm philosophy and run/hold states. Clause/record: ISO 13849-1 validation report VR-2025-011; PQ-2025-006 uptime rollup evidences MTBF 26,000 h, with CMMS logs referencing MTTR 14 min. Steps: align spare kits to commonality; stage tools shadow board; define training based on fault trees; review alarm rationalization monthly; test e-stop SLS (safely limited speed) quarterly. Risk boundary: MTTR exceeding 20 min over three consecutive events triggers a root-cause workshop. Q&A: Where can maintenance find “where to buy ASFL vacuum sealerealer”? Answer: purchasing uses the qualified vendor list in IQ-2024-ASFL-017.

Control Plan and Records

| CPP | CQA | Sampling | Record |

|---|---|---|---|

| Seal temp, force | Peel strength | 1 per 30 min | OQ-2025-014 |

| Vacuum endpoint | Leak decay | 1 per 60 min | PQ-2025-006 |

| Torque window | Indentation | Event-based | SAT-2025-ASFL-009 |

Summary: the ASFL control stack—PID thermal management, torque-gated kinematics, ISA-95/OPC UA integration, and validated records—supports FPY above 99%, false-reject near 0.3% at 185–190 °C and 0.9 s dwell, and energy near 0.018–0.024 kWh/pack. Safety meets ISO 13849-1; records meet Annex 11 and 21 CFR Part 11. For procurement and training logistics, the engineering handbook lists qualified sources and change-part matrices, including notes on where to buy ASFL vacuum sealerealer and small-bag formats. This aligns with the defined MTBF/MTTR targets for the ASFL, providing a clear centerline profile for sustained operation.