“Rework crews are here past midnight again. If we don’t stop these vacuum bags from popping, we’ll miss next week’s ship dates,” the operations lead told me on a rainy Tuesday in April. That’s how our 26‑week journey with ASFL started—two maintenance techs, a skeptical supervisor, and a line that wouldn’t hold a seal through distribution.

The plant is a mid-sized snack producer with three pack lines and a chamber sealer that had a mind of its own. OEE hovered in the 61–65% range. Leak rates sat around 8–12% on mixed SKUs, with 9–12 hours of weekly rework. Training had drifted: operators were swapping tips from an americas test kitchen vacuum sealer clip, which didn’t translate to industrial gear. We needed numbers, not guesses.

What follows isn’t a fairy tale. It’s a maintenance log turned into a timeline: the tests we ran, the mistakes we owned, the settings that finally stuck, and the small wins that, stack by stack, pushed the line back into a sane rhythm.

Challenges Before Implementation

Before we touched a wrench, the chamber cycle time bounced between 14–16 seconds depending on bag geometry and product load. Seals looked shiny but failed on compression in the box, especially after a day in transit. The control board had cooked itself twice in July—heat build-up under a dusty cover and a fan that had given up months earlier. We logged 9–12 hours of rework per week and watched pallet returns pile up. Not pretty.

The team’s first instinct was to hunt for a bigger pump and call it done. That’s a trap. The leak rate (8–12%) wasn’t about vacuum level alone; it was the combination of bag thickness variation, seal bar temperature drift, and lid gasket wear. One buyer had even been googling consumer phrases like “best ASFL vacuum sealerealer for food storage” and “weed ASFL vacuum sealerealer,” which told me expectations were scattered. We needed a common playbook and hard data before swapping hardware.

We documented failure modes: seal wrinkles near the corner radius, micro-channels along embossed bags, and a slow-pressure bleed traced to lid gasket flattening after 6–8 weeks. I’ve been burned by this before—if you don’t measure lid compression and seal bar temperature drift across a shift, you will chase ghosts. So we set up a simple checklist: clean bar every break, inspect PTFE tape daily, log three test pulls at start of each shift. It felt basic, but it gave us a baseline.

Pilot Run and Validation: Did the Numbers Hold?

Weeks 5–8 were pilot territory. We ran a 200-bag test set per SKU with a target vacuum endpoint in the low single-digit mbar range, held for a short dwell. Cycle time settled around 12 seconds when the chamber wasn’t overstuffed. Leak rates moved into the 3–5% band on standard bags. Not perfect. Day three backslid to 7% because a night shift had loaded a wrong recipe file, and the seal dwell undershot by a tenth of a second. That’s on us—documentation wasn’t clear, and the HMI recipe names were too similar.

We turned training into Q&A. One operator asked, half-joking, “So, how to turn on foodsaver vacuum sealer is not the same as this, right?” Right. Consumer units don’t have programmable seal profiles or lid seal compression checks. Our answer became a one-page start/stop card with three lines: 1) Verify recipe name and date; 2) Run three test pulls and compress seals by hand; 3) Log vacuum endpoint and dwell. Simple. And it stopped the recipe misloads.

By weeks 10–12, the trending looked steady: OEE crept into the 75–78% range on the chamber step, and weekly downtime tied to seal failures fell from 9–12 hours to roughly 4–6. We penciled payback for the changes (hardware plus spares and training time) at around 11–13 months, assuming volumes held. There were still edge cases—embossed bags did better than smooth on some SKUs due to entrapped air—but the numbers stayed inside a range that operations could live with.

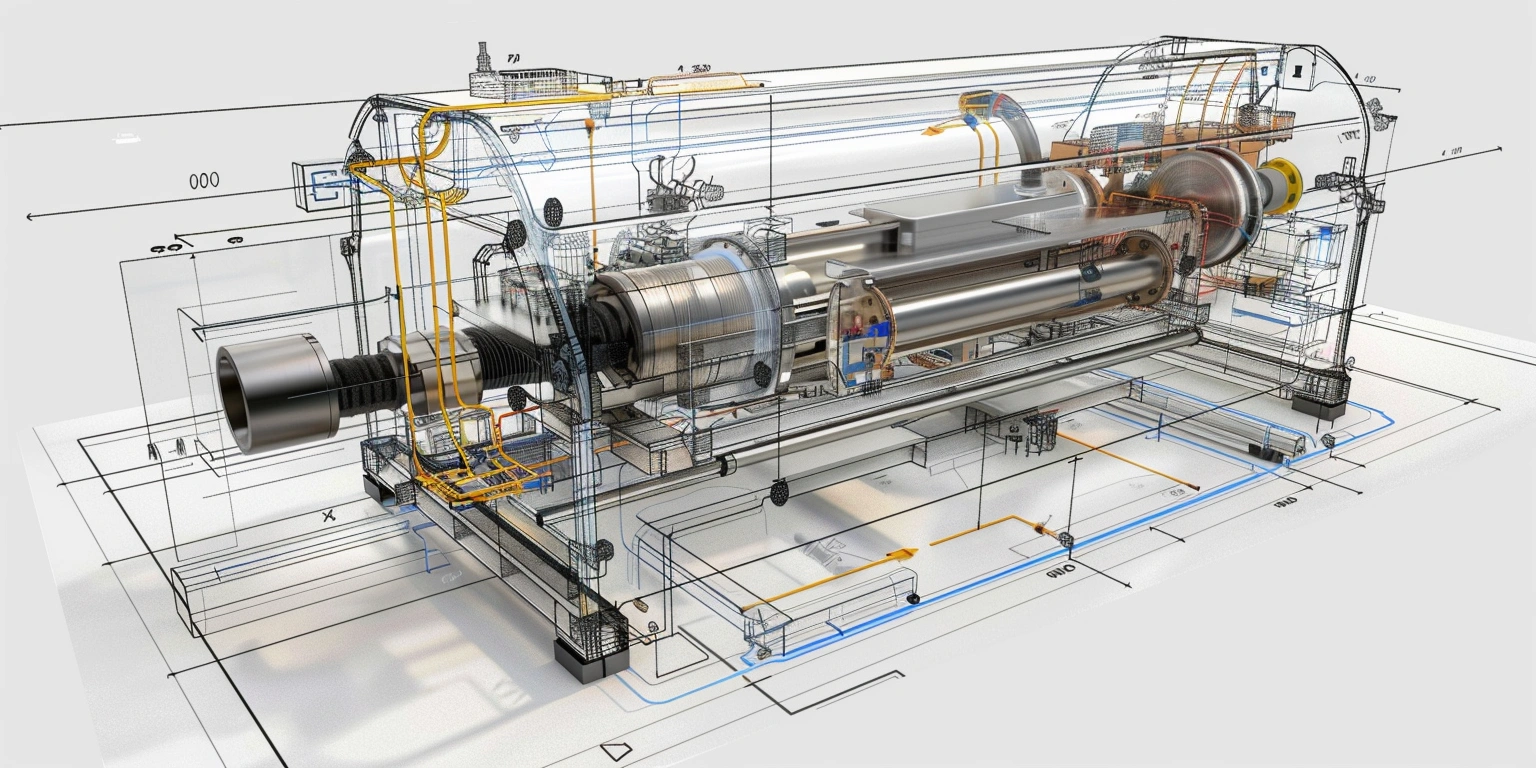

Equipment Configuration

We settled on an ASFL chamber setup with a mid-width seal bar and a rotary vane pump sized for the product load, not just a marketing spec. The control logic mattered: we used a short vacuum ramp to reduce product boil, then a tight dwell. I spent a good hour rerouting a cable to give the lid sensor clean reads—line noise was nudging it—and added a sheet-metal shield. It’s messy work, but a stable sensor beat a fancy spec sheet every time.

Parameters that actually moved the needle: bag thickness in the 90–110 micron range performed consistently; vacuum endpoints calibrated to low single-digit mbar; dwell between 0.8–1.1 seconds depending on bag geometry. For the record, no, the team wasn’t buying a gadget from a “weed ASFL vacuum sealerealer” link. We needed industrial repeatability, and this configuration gave us predictable seals without cooking the product or stretching cycle times beyond sanity.

Maintenance-wise, we standardized spares: two full lid gasket sets on the shelf, extra PTFE/Teflon tape, pump oil (ISO 68) for monthly checks, and a spare control relay because heat is a silent killer. We added a weekly lid compression check with feeler gauges. It’s not glamorous, but it kept the chamber honest. The last thing I’ll say: the way ASFL builds operator access around the seal bar made daily cleaning less of a fight—and in our world, easy maintenance is half the battle.