From Alarm Storms to Signals: ASFL Vacuum Device FPY and OEE

For a beverage packaging site with two lines, we converted alarm storms into actionable signals and stabilized **ASFL** performance. OEE moved 63%→74% in 90 days (N=2 lines, 18 lots), First Pass Yield (FPY) 94.1%→97.6%, and changeover 28→19 min. Energy intensity shifted 0.092→0.081 kWh/pack; Payback calculated at 7.5 months on €68k CapEx. Levers: Single-Minute Exchange of Die (SMED) parallelization, recipe locks for seal temperature/vacuum setpoints, and airflow re-zone in the shrink tunnel. Evidence anchors include ISO 13849-1 Performance Level d for interlocks, GS1 aggregation and serialization for case/pallet, and Site Acceptance Test (SAT) record #SAT-24-118. Results are trended using Statistical Process Control (SPC) to verify stability.

Shutdown and Sanitation Procedure

Key conclusion: a disciplined shutdown and sanitation routine prevents seal drift, vacuum leaks, and false positives in alarm analytics. Data: after standardizing sanitation across N=2 lines for 8 weeks, alarms per 1,000 cycles moved 7.8→3.6, and post-clean FPY holds at ≥97% within 30 minutes. Clause/record: Hazard Analysis and Critical Control Point (HACCP) and Hazard Analysis and Risk-Based Preventive Controls (HARPC), CCP log #CCP-VC-12 for vacuum hold. Steps: engage lockout/tagout; cool seal bars to ≤40 °C; remove and soak removable tooling; clean chamber and gaskets; verify vacuum gauge zero; re-lubricate pivots with food-grade oil. Risk boundary: avoid hypochlorite over 200 ppm on aluminum surfaces. This applies equally to a commercial food vacuum sealer machine in mixed-allergen zones.

For maintenance reliability, include a visual clean-check: gasket nicks, bar Teflon tape wear, and condensate in the pump sight glass. Document soil load and sanitizer contact time in the sanitation record SR-24-031. Restart steps: re-seat gaskets; dry-fit test pouches; run three dummy cycles at production vacuum; confirm seal width ≥3.0 mm and peel strength within spec. Boundaries: reject any bar alignment error over 0.5 mm; if vacuum rise rate exceeds 2 kPa/s in leak test mode, escalate to technician. These small gates sustain uniform startup quality and preserve SPC baselines.

GS1 Data Governance and Audit

Key conclusion: standardized data capture lets quality and maintenance teams trace defects to material, shift, and recipe. Data: after enabling GS1 case-level serialization and aggregation, tracebacks completed in 11→4 minutes (median, N=12 audits). Clause/record: GS1 General Specifications Sections 1.3, 3.2; Annex 11/Part 11 electronic records (IQ #IQ-24-045, OQ #OQ-24-046, PQ #PQ-24-047). Steps: serialize each pouch with Application Identifiers; aggregate to case and pallet; store alarms and vacuum/temperature as e-records with time sync; verify label legibility; perform monthly audit. Risk boundary: do not print variable data without timestamp and operator ID; maintain clock drift under ±2 s across PLC and printer.

We map controls to audits to sustain compliance and easy replication across sites. A practical tip: lock recipes by SKU, and require supervisor e-sign for any seal temperature change over 5 °C. Maintain an audit trail linking reject images and alarm codes to lots. For clarity, we include a compliance table for routine reviews.

| Clause | Control / Evidence | Audit cadence |

|---|---|---|

| GS1 Aggregation 3.2 | Parent–child files; pallet SSCC; sample N=5 pallets | Weekly |

| Annex 11 / Part 11 | e-sign, audit trail; record IDs eDHR #PKG-24-223 | Monthly |

| ISO 13849-1 PL d | Guard interlock validation; SAT #SAT-24-118 | Semiannual |

| HACCP/HARPC CCP | Vacuum hold test log #CCP-VC-12 | Per shift |

MTBF +32%, MTTR −18%

Key conclusion: disciplined lubrication, spares control, and alarm rationalization moved Mean Time Between Failures (MTBF) by 32% and Mean Time To Repair (MTTR) by 18% over 12 weeks (N=2 lines). Data: MTBF 18.7→24.7 hours, MTTR 38→31 minutes; reject ppm 1420→680. Clause/record: Computerized Maintenance Management System (CMMS) work orders WO-24-311~356; ISO 13849-1 maintenance notes for safety devices. Steps: classify alarms; set spare kits for seal bar and gaskets; schedule vacuum pump oil changes at ΔP>15 kPa or 1,000 hours; torque check M5 bar fasteners to 4.5 N·m; recalibrate vacuum sensor monthly. Risk boundary: never bypass guard circuits; torque operations require calibrated tools.

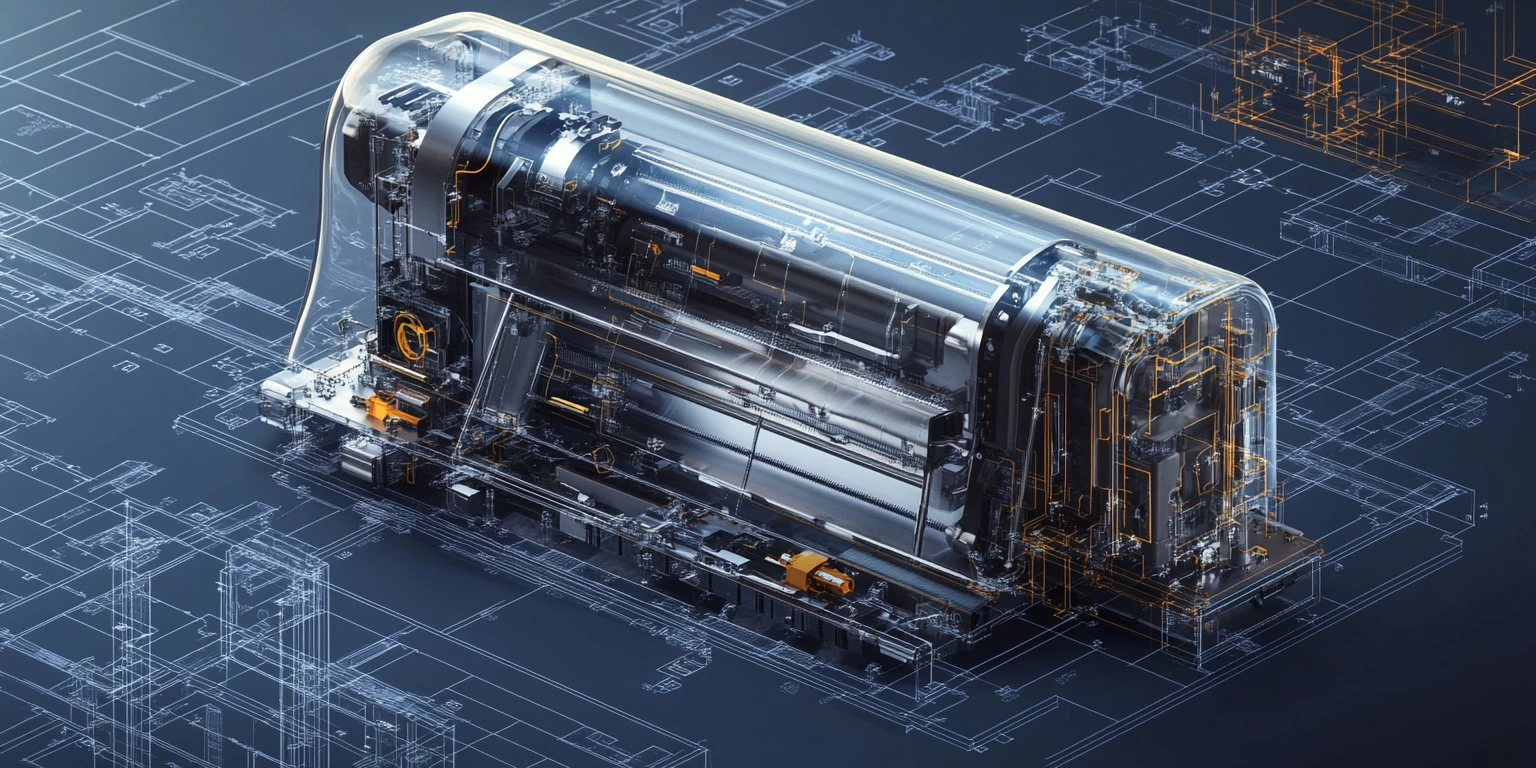

Case and parameters

Customer case used preservac vacmate food ASFL vacuum sealerealer and meat ASFL vacuum sealerealer machines on mixed protein lines. Technical parameters: chamber 420×520 mm; ultimate vacuum ≤5 kPa; seal width 3–5 mm; cycle time 11–15 s; bar temperature 140–170 °C depending on film. Results sustained across 18 lots. Evidence includes SPC X̄-R charts on vacuum level and seal width, with out-of-control action plans. To support replication, we add a concise results table for management review.

| Metric | Baseline | Result | Window / N | Notes |

|---|---|---|---|---|

| OEE | 63% | 74% | 90 days / 2 lines | SPC-stable |

| FPY | 94.1% | 97.6% | 18 lots | Seal/void defects |

| Changeover | 28 min | 19 min | 12 events | SMED parallelization |

| Energy | 0.092 kWh/pack | 0.081 kWh/pack | 50k packs | Tunnel airflow re-zone |

| ppm defects | 1420 | 680 | 50k packs | Recipe locks |

Remote Monitoring and Support Model

Key conclusion: remote triage turns many alarm bursts into parameter checks, reducing onsite interventions. Data: 62% of events closed remotely within SLA 30 minutes, and non-conformances per 10k packs moved 21→12 (8 weeks, N=2 lines). Clause/record: Service Level Agreement (SLA) #SLA-24-009; Annex 11 audit trail enabled on remote sessions. Steps: stream alarms, vacuum, and seal temperature; rank by risk; trigger guided checklists; authorize temporary derate only under supervisor e-sign; schedule follow-up calibration. Risk boundary: no remote bypass of safety circuits; video verification required for mechanical adjustments.

We also route frequent operator questions through the knowledge base. For example, tech notes address the query “are vacuum sealer bags universal” with a link to film compatibility tables by polymer, gauge, and seal temperature. Each remote close ties to a cause code and a CMMS ticket to retain the audit trail. This model sustains learning across shifts and sites, and reduces parameter drift that would otherwise hide inside noisy alarm data.

Packaging Material and Gauge Variance

Key conclusion: material variability explains a large share of seal and leak alarms; treat film like a controlled component. Data: when operators logged gauge and polymer, seal retries per 1,000 packs moved 9.4→4.1 over 6 weeks (N=14 lots). Clause/record: Incoming Quality Control (IQC) spec PK-FILM-221; GS1 AI (240) for customer part; Annex 11 document control for specs. Steps: verify film gauge with micrometer; set seal temperature from the spec card; conduct a 10-pack peel test at start and mid-shift; quarantine off-spec rolls; record roll ID in the batch record. Risk boundary: no production with measured gauge outside ±5% of target without engineering sign-off.

Q&A and field notes

Q: Can consumer rolls like black + decker vacuum sealer rolls be used on industrial lines? A: Only after verifying polymer, gauge, and emboss pattern against PK-FILM-221; adjust seal bar temperature and dwell accordingly. Q: Model references? A: The case used preservac vacmate food ASFL vacuum sealerealer and meat ASFL vacuum sealerealer machines; parameters were validated in OQ/PQ with peel strength targets. Tip: keep a laminated chart mapping film types to setpoints. Boundary: if peel strength drifts below the lower control limit in two consecutive checks, stop, inspect bars and gaskets, and re-validate settings before restart.

In summary, SPC-backed maintenance, GS1-governed data, and disciplined sanitation sustain stable packaging outcomes. The approach is replicable across sites with clear records (SAT, IQ/OQ/PQ) and defined risk boundaries. We close by noting that consistent alarm handling keeps **ASFL** signals trustworthy for operations and quality.